An automotive paint booth is a specialized enclosure designed to provide an optimal environment for refinishing vehicles. By controlling various factors such as temperature, humidity, and airflow, these booths ensure that the painting process is not only efficient but also results in high-quality finishes. The significance of an automotive paint booth goes beyond mere convenience; it plays a crucial role in preventing contaminants, such as dust and debris, from ruining the paint job, ultimately enhancing the durability and appearance of the vehicle's exterior.

Understanding how an automotive paint booth operates is essential for those in the automotive repair and restoration industries. The intricate system of filtration and ventilation within the booth creates a controlled atmosphere that allows technicians to apply paint more accurately and consistently. The booth's design facilitates the evaporation of solvents, reduces drying time, and improves the overall efficiency of the painting process. With the increasing demand for high-quality refinishing services, the automotive paint booth has become a vital asset for professionals aiming to meet or exceed customer expectations in vehicle aesthetics.

An automotive paint booth is a specialized enclosure designed to provide an optimal environment for applying paint to vehicles during the refinishing process. These booths are equipped with advanced ventilation systems that control air quality, temperature, and humidity levels, ensuring a consistent application that enhances the finish and durability of the paint. By keeping the booth clean and isolated from external contaminants, the risk of dust and debris affecting the paint job is significantly reduced, resulting in a smoother and more professional finish.

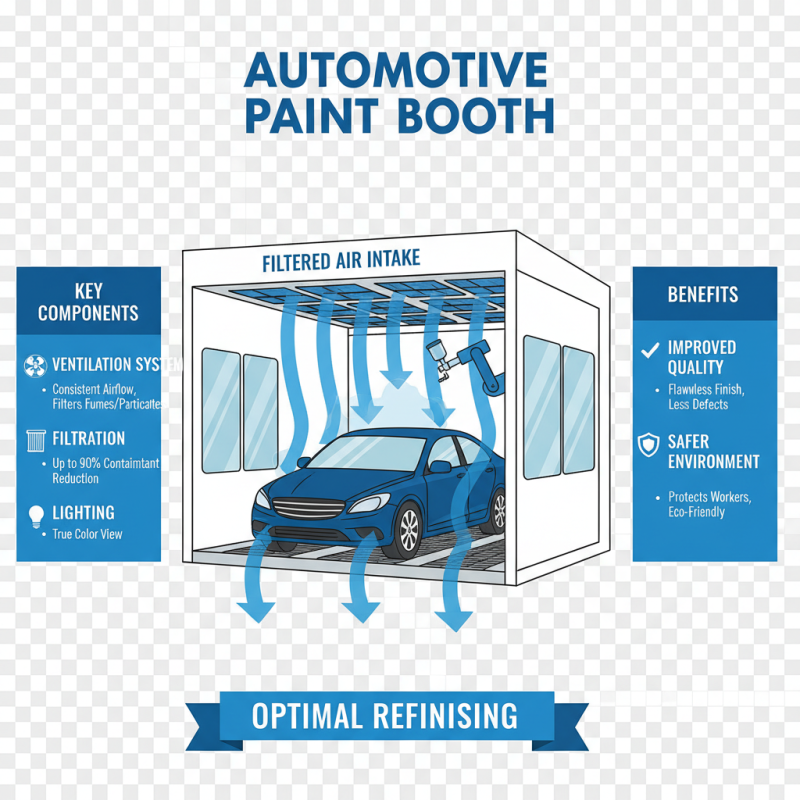

The operation of an automotive paint booth involves several key components. First, a filtration system captures airborne particles, ensuring only clean air enters the booth. Next, temperature controls allow technicians to maintain ideal conditions that accelerate the drying process of the applied paint. Additionally, proper lighting within the booth ensures that painters can clearly see their work, facilitating precision and attention to detail. Overall, the design and functionality of an automotive paint booth are crucial in achieving high-quality refinishing results while protecting both the vehicle and the environment from harmful overspray.

| Feature | Description |

|---|---|

| Purpose | To provide a controlled environment for automotive painting, ensuring quality finishes. |

| Ventilation System | Equipped with a specific ventilation system to eliminate overspray and toxic fumes. |

| Lighting | Bright, even lighting that allows for accurate color matching and visibility during the painting process. |

| Temperature Control | Maintains optimal temperature for paint curing and application. |

| Types | Various types include downdraft, crossdraft, and side draft booths. |

| Application Process | Preparation, painting, and curing phases to ensure a durable finish. |

| Safety Features | Includes fire suppression systems and personal protective equipment for workers. |

An automotive paint booth is a specialized environment designed to allow for the safe and efficient spray painting of vehicles. Understanding the key components of a paint booth is crucial for ensuring optimal performance and quality in car refinishing. One of the primary elements is the ventilation system, which not only provides a consistent airflow but also filters out harmful particulates and fumes. According to industry standards, effective ventilation can reduce airborne contaminants by up to 90%, significantly improving the working conditions and finish quality.

Another critical component is the lighting system, which must provide uniform visibility to ensure accurate color matching and detail work. Studies indicate that booths equipped with high-quality lighting can enhance color perception and reduce the likelihood of errors during the painting process. Moreover, the structure of the booth itself plays a vital role in controlling the environment; maintaining temperature and humidity levels is essential to achieve optimal paint adhesion and drying times. Reports suggest that consistent temperature control can speed up drying times by 30%, thereby increasing productivity and throughput in auto body shops.

In summary, the integration and proper management of ventilation, lighting, and environmental control systems in an automotive paint booth are fundamental to achieving high-quality paint finishes and efficient workflow in car refinishing.

An automotive paint booth is an essential facility for car refinishing, providing a controlled environment for applying paint and finishing products. The paint booth operates through a systematic process designed to ensure optimal application, safety, and quality. Initially, the vehicle is cleaned and prepped to remove any contaminants that could compromise the paint finish. Once inside the booth, the next step involves setting the appropriate temperature and humidity levels. Research indicates that maintaining specific conditions during the painting process can reduce defects and enhance the durability of the paint finish, with optimal temperatures typically ranging between 65°F to 80°F.

In the booth, air circulation plays a crucial role. Equipped with specialized exhaust systems, a paint booth ensures the removal of harmful fumes and overspray while simultaneously providing a steady supply of fresh air. The spraying process itself is then executed using high-efficiency spray guns that can atomize paint particles evenly, promoting a smooth finish. According to industry data, the use of advanced energy-efficient paint booths can reduce volatile organic compound (VOC) emissions by up to 30%, contributing to both environmental protection and compliance with regulatory standards. Once the painting is complete, the curing phase is initiated, often achieved through controlled heating elements, which facilitate quicker drying times and better adhesion of the paint, ensuring a high-quality final product.

Temperature and airflow control play a crucial role in the automotive paint booth environment, significantly impacting the quality and durability of car refinishing. According to industry research, optimal temperature settings in paint booths should typically range between 65°F to 85°F (18°C to 29°C). This temperature range ensures that the paint adheres properly and cures effectively, reducing the risk of defects such as runs, sags, and poor adhesion. A consistent temperature helps maintain the viscosity of the paint, allowing for a smoother application and enhancing the overall finish quality.

Airflow control is equally important, as it affects the drying time and the final appearance of the paint job. Effective ventilation systems are designed to achieve a balanced airflow that minimizes the accumulation of overspray while ensuring that fresh air is continuously supplied. Studies indicate that booths with well-regulated airflow can reduce the drying time by up to 30%, allowing for quicker project turnaround while maintaining high-quality results. Moreover, controlling air movement helps prevent contaminants from settling on wet paint surfaces, significantly lowering the likelihood of imperfections. Together, these factors create an environment that not only enhances productivity but also ensures that car refinishing meets the high standards expected in the automotive industry.

When operating an automotive paint booth, safety measures are paramount to ensure the well-being of workers and the environment. Proper ventilation is crucial; paint booths must be equipped with effective exhaust systems to remove harmful vapors and maintain air quality. Workers should always wear personal protective equipment (PPE), including respirators, gloves, and protective clothing, to minimize exposure to chemicals. Additionally, it’s essential to have proper training in handling paints and solvents, understanding material safety data sheets (MSDS), and emergency procedures in case of spills or accidents.

Best practices for paint booth usage extend to both equipment maintenance and operational protocols. Regular inspections of the booth ensure that filters, lights, and spray systems are functioning correctly. Maintaining cleanliness in and around the booth prevents the accumulation of flammable materials, reducing fire hazards. Furthermore, it's important to follow proper paint application techniques, ensuring that overspray is minimized and that the working area is organized. By adhering to these safety measures and best practices, automotive professionals can create a safer and more efficient environment for car refinishing.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.