When it comes to the best curing oven options for 2026, precision and efficiency are paramount. Industry expert Dr. Emily Carter once stated, "A well-designed curing oven can make or break your final product." This highlights the critical role of curing ovens in various manufacturing processes. A reliable curing oven ensures that each batch is consistent, meeting the required specifications.

However, navigating the market can be challenging. There are many features to consider. Different models offer varying levels of control and efficiency. Manufacturers need to assess their specific needs before making a decision. Some may prioritize energy efficiency while others focus on size and capacity.

Real-world feedback often reveals that the best choice isn’t always the most expensive one. Many users report dissatisfaction, citing issues with temperature fluctuations. Such inconsistencies can compromise product quality. Reflection on user experiences leads to valuable insights. This journey toward the ideal curing oven requires careful consideration and adjustments along the way.

Curing ovens play a vital role in various precision applications, especially in the fields of materials science and electronics. These ovens ensure uniform heat distribution, crucial for achieving desired material properties. According to a recent industry report, improper temperature control can lead to defects in products, resulting in increased waste and rework costs. A study indicated that 35% of manufacturing defects are linked to inadequate curing processes.

Precision in curing ovens is essential for coatings, adhesives, and composite materials. Precise temperature settings ensure optimal chemical reactions during curing. In fact, research highlights that fluctuations in temperature can alter the molecular structure of materials. This can compromise their strength and longevity. An alarming statistic shows that nearly 40% of businesses report issues with curing consistency, leading to inefficiencies in production.

Moreover, efficiency is more than just energy consumption. It also involves reducing cycle times while maintaining quality. Some current models promise quicker curing times through advanced technology. However, these innovations need to be weighed against their costs and reliability. The journey to finding the ideal curing oven must involve careful consideration of both precision and efficiency. A lack of reflection on these factors can lead to detrimental business outcomes.

| Model | Temperature Range (°F) | Capacity (Cubic Feet) | Features | Energy Efficiency Rating |

|---|---|---|---|---|

| Curing Oven A | 200 - 500 | 10 | Digital Controller, Humidity Control | A+ |

| Curing Oven B | 150 - 400 | 8 | Programmable Settings, Quick Heat | A |

| Curing Oven C | 180 - 450 | 12 | Dual-zone Temperature Control | B+ |

| Curing Oven D | 250 - 550 | 15 | User-friendly Interface, Energy-Saving Mode | A++ |

| Curing Oven E | 200 - 600 | 20 | Remote Monitoring, High Precision | A+ |

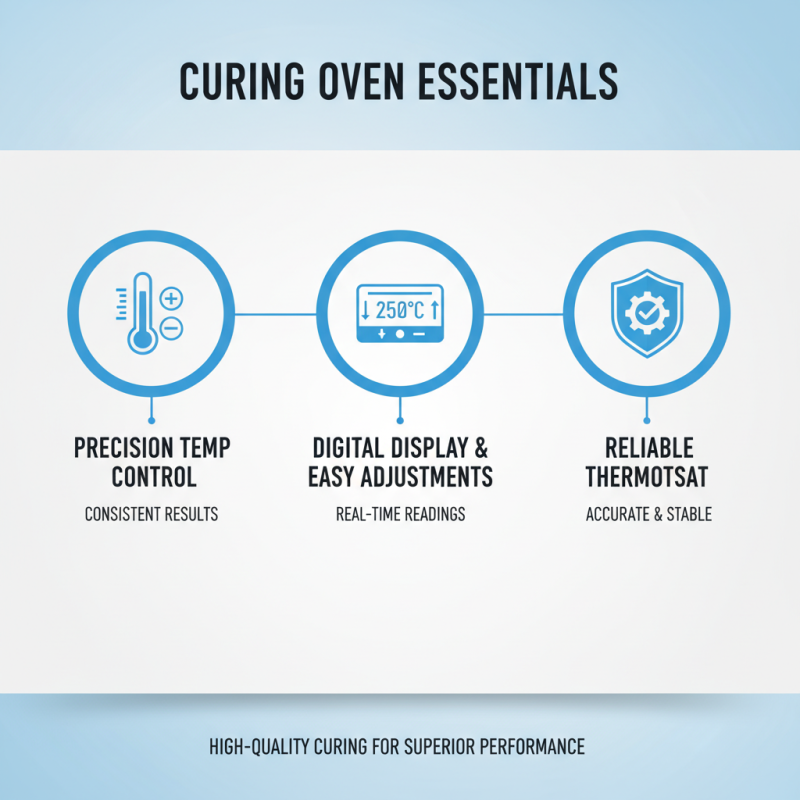

When searching for a high-quality curing oven, there are key features to consider. Precision temperature control is crucial. It ensures consistent results every time. Look for ovens that allow easy adjustments. Digital displays can provide real-time temperature readings. Make sure the oven has a reliable thermostat for accuracy.

Efficiency is also important. The design should allow for even heat distribution. Some models may have issues with hot spots. Check user reviews for feedback. Insulation plays a role too. Good insulation retains heat, saving energy and time.

Consider the size and capacity as well. Will it fit your workspace? A larger oven may be tempting, but it can consume more energy. Reflect on how often you'll use it. Size matters, but so does your workflow. Accessories, such as racks, can enhance utility, yet they may increase cost. Choose wisely based on your specific needs and goals.

When choosing a curing oven, precision is key. The right model can greatly affect the final product's quality. Look for ovens that offer adjustable temperature settings. This feature allows for better control during curing processes. Some ovens also have humidity control, which enhances curing consistency.

Pay attention to specifications like chamber size and airflow design. Larger chambers can accommodate bigger batches, but they may not heat evenly. A well-designed airflow system ensures that each item is cured uniformly. Consider the energy consumption as well. Some models are energy-efficient, which might lower long-term costs.

It’s important to read user reviews. Customers often share insights about performance and reliability. Not all models live up to expectations, and it's crucial to avoid common pitfalls. Users frequently mention the need for accurate calibration. Without it, results can vary drastically.

Curing ovens are essential for various industries, particularly in manufacturing and artisanal crafts. They provide controlled environments to ensure proper curing of materials. This analysis focuses on efficiency in curing oven options available in 2026.

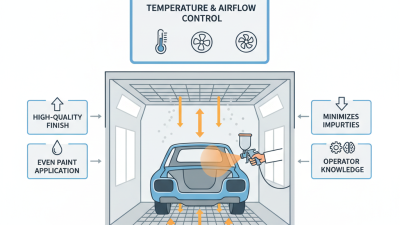

When selecting a curing oven, several factors influence efficiency. Temperature control is vital. A deviation of even a few degrees can impact curing quality. Ovens that offer precise temperature adjustments tend to yield better results. Some models feature programmable settings, which can optimize heating cycles. However, relying too heavily on technology can lead to neglect of manual checks. Balancing automation and human oversight is critical.

Another consideration is airflow circulation. Optimal airflow ensures even heat distribution. Some ovens struggle in this area, leading to uneven curing. Observations reveal that units with adjustable fan speeds can improve outcomes. However, they may also introduce complexity, requiring careful monitoring. Ultimately, a thorough understanding of these variables can help users make informed choices.

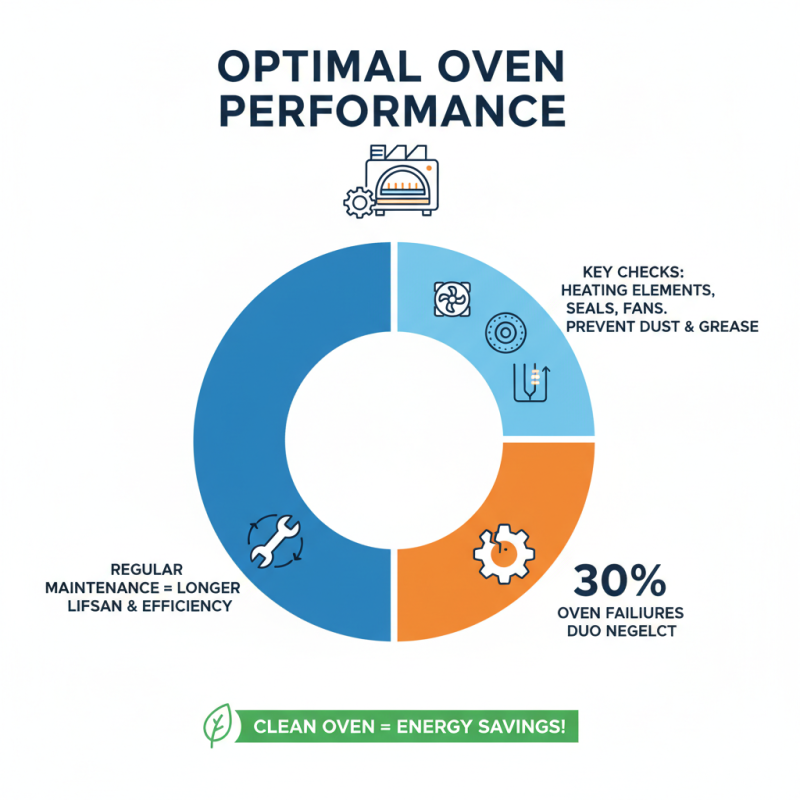

Curing ovens are crucial for achieving optimal results in various industries, including manufacturing and food processing. Regular maintenance is key to enhancing their lifespan and efficiency. According to industry experts, around 30% of oven failures stem from neglecting routine care. It’s essential to conduct regular inspections of heating elements, seals, and fans. Dust and grease can accumulate, compromising performance. A clean oven functions more efficiently and reduces energy costs.

Another useful tip involves monitoring temperature accuracy. Inconsistent temperatures can lead to flawed products. Calibrating the oven regularly ensures product integrity. Industry reports suggest that up to 15% of production defects result from temperature fluctuations. Additionally, consider the gasket condition. Worn-out gaskets can cause heat loss. Replacing them promptly improves energy efficiency and cures more evenly.

Don't forget about software updates if your oven is technologically advanced. These updates can fix bugs that affect performance. Ignoring software issues might lead to inefficiencies. Maintenance schedules should be followed rigorously. A lapse can influence overall productivity. In the end, investing time in maintenance pays off. It enhances the performance of curing ovens significantly.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.