In today's highly competitive automotive industry, the demand for high-quality vehicle finishing has never been greater. A well-equipped auto shop relies heavily on the effectiveness of its facilities, and one of the most critical components is the **car paint booth**. According to the Grand View Research report on the global automotive paint booth market, the industry is projected to reach a value of USD 1.8 billion by 2026, driven by the growing need for efficient and environmentally friendly painting solutions in automotive repair and manufacturing.

Choosing the right **car paint booth** is essential not only for achieving a flawless finish but also for optimizing workflow and ensuring compliance with environmental regulations. Factors such as size, ventilation system, filtration quality, and energy efficiency play significant roles in determining the best fit for an auto shop's specific needs. As the sector evolves with innovations in technology and sustainability, shop owners must stay informed about the latest advancements in **car paint booth** design and functionality to enhance their operations and meet customer expectations. Understanding these elements is paramount for any auto shop looking to thrive in a demanding market.

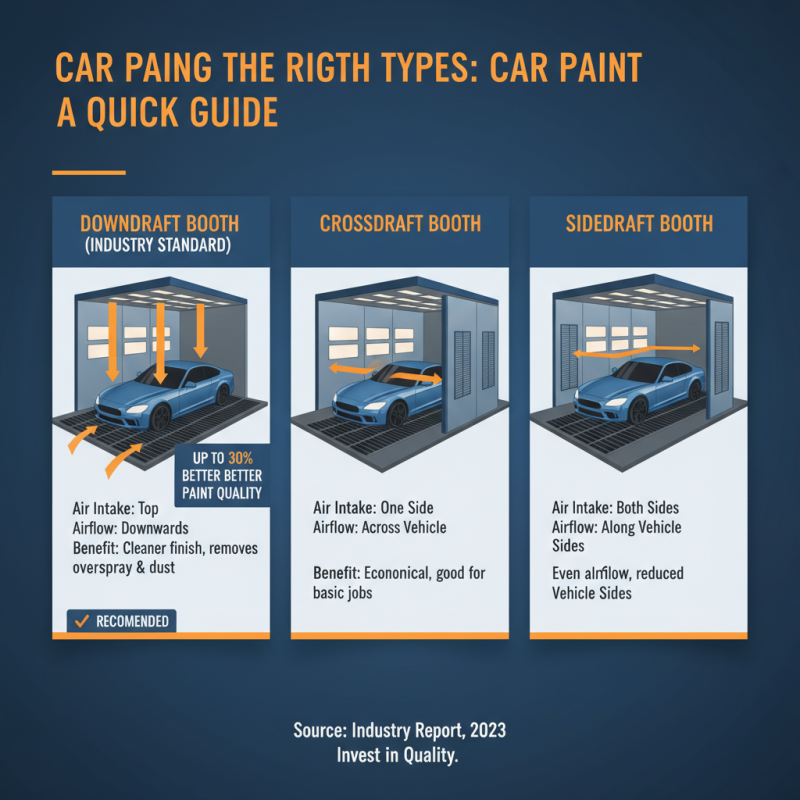

When it comes to selecting the right car paint booth for your auto shop, understanding the different types available is crucial. There are three primary categories: downdraft, crossdraft, and side-draft booths. Downdraft booths are considered the industry standard, featuring air intake positioned at the top, allowing airflow to move downwards. This design helps create a cleaner environment by pulling overspray and dust away from the vehicle. A recent industry report indicates that shops using downdraft booths see an average improvement in paint quality by up to 30%, making them a lucrative investment.

Crossdraft booths, on the other hand, utilize a lateral airflow system. While they are generally more affordable, they might not provide the same level of finish as downdraft booths. Side-draft booths combine elements of both designs, introducing airflow from one side and exhausting it through the other. While not as common, they can be effective in specific shop configurations. According to data from the Automotive Service Association, more than 50% of shops are moving towards downdraft systems for their efficiency and reduced rework costs.

Tips: When choosing a paint booth, consider your shop's space and workflow. Evaluate not just the purchase price but also the long-term operational costs, including ventilation and energy consumption. Investing in a booth that aligns with your shop's needs can significantly impact productivity and customer satisfaction. Always consult with industry professionals to ensure you're making an informed decision tailored to your specific requirements.

When selecting a car paint booth for your auto shop, assessing your space and layout is crucial. Begin by measuring the available area to determine how much room you can allocate for the booth. A proper understanding of the dimensions will not only help you find a booth that fits but also ensure that it meets operational requirements. Consider the height, width, and depth of the booth, keeping in mind the vehicles you typically service. Additionally, it’s important to account for accessibility, allowing enough space for easy entry and exit of vehicles as well as safe movement for employees.

The layout of your shop should also influence your decision. It’s advisable to think about how the paint booth will integrate with other areas of your business, such as the prep and finishing stations. Positioning the booth in a location that optimizes workflow can significantly enhance productivity. Ensure adequate space for equipment, ventilation systems, and safety protocols. An efficient layout will minimize bottlenecks and allow for a streamlined painting process, ultimately contributing to better quality and turnaround times in your auto shop.

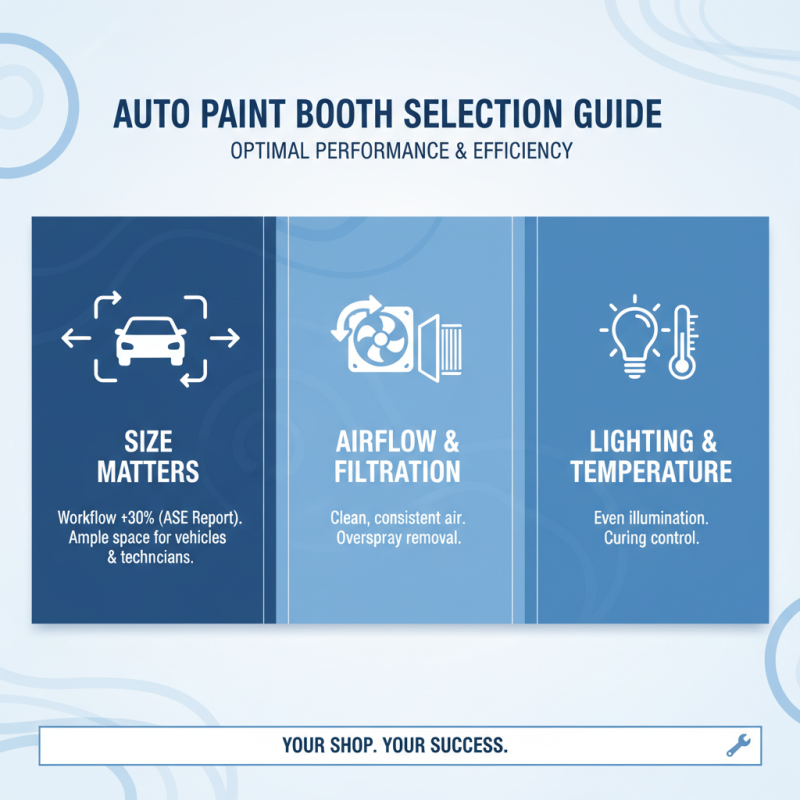

When selecting a paint booth for your auto shop, several key features should guide your decision to ensure optimal performance and efficiency. First and foremost, the booth's size is critical. According to a report from the National Institute for Automotive Service Excellence (ASE), an adequately sized booth can improve workflow by up to 30%. This means considering the dimensions of vehicles you typically service and ensuring that the booth allows for easy maneuverability, effective airflow, and sufficient space for technicians to operate.

Another essential feature to evaluate is the ventilation system. A well-ventilated paint booth not only ensures a safe working environment by reducing harmful fumes but also contributes to better paint application. The American Society for Testing and Materials (ASTM) suggests that booths with a minimum air exchange rate of six to ten air changes per hour provide the best conditions for paint curing and drying. Additionally, look for booths equipped with effective filtration systems that capture overspray and contaminants, which can significantly enhance the quality of finish and reduce the risk of rework, ultimately saving time and resources.

Lastly, it's important to consider the booth's lighting. Quality lighting impacts the technician's ability to spot imperfections during the painting process. A recent study by the Occupational Safety and Health Administration (OSHA) highlights that bright, consistent lighting can improve paint job quality by as much as 20%. Selecting a booth with optimal fluorescent or LED lighting can lead to improved visibility and a more precise application, ensuring your shop maintains a high standard of workmanship.

When selecting a car paint booth for your auto shop, understanding your budget constraints is crucial. Begin by assessing the overall costs associated with different booth options, including initial purchase price, installation expenses, and ongoing maintenance fees. Consider whether a new or used booth fits your budget better, and factor in potential costs for modifications or upgrades that may enhance efficiency or performance.

Cost-effectiveness is determined not only by the upfront investment but also by the long-term savings that an efficient paint booth can provide. Energy efficiency, reduced paint waste, and improved workflow can translate into significant savings over time. Evaluate the features that offer better performance and reliability, which can lead to increased productivity and customer satisfaction. Weigh these factors against cost to ensure that your investment aligns with your shop's financial goals while meeting operational needs.

| Model | Price ($) | Size (ft) | Airflow (CFM) | Energy Efficiency Rating | Warranty (Years) |

|---|---|---|---|---|---|

| Standard Model | 5000 | 20 x 10 | 2000 | B | 2 |

| Deluxe Model | 7500 | 22 x 12 | 2500 | A | 3 |

| Premium Model | 10000 | 25 x 15 | 3000 | A+ | 5 |

| Compact Model | 4000 | 15 x 10 | 1500 | C | 1 |

When selecting a car paint booth, one of the most critical considerations is ensuring compliance with safety and environmental regulations. Paint booths are subject to various industry standards that focus on controlling emissions and minimizing hazards associated with paint application. These regulations often require specific ventilation systems and filtration technologies to reduce volatile organic compounds (VOCs) that are released into the atmosphere. Auto shop owners must familiarize themselves with local, state, and federal requirements to ensure their paint booths meet these necessary standards.

In addition to emissions control, safety features in paint booths play a vital role in protecting both workers and the surrounding environment. Adequate fire suppression systems, proper electrical installations, and non-toxic materials are essential to creating a safe workspace. Furthermore, an efficient operational design will help prevent cross-contamination of paint materials, further adhering to environmental preservation efforts. Ensuring that the chosen paint booth aligns with the latest safety standards not only protects your employees but also enhances the reputation of your auto shop in a competitive market.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.