Choosing the right small paint booth can significantly impact your painting efficiency and the quality of your work. According to industry reports, the global paint booth market is projected to reach $3.5 billion by 2026, with small booths gaining popularity. This growing demand highlights the importance of making an informed choice.

Several factors should influence your decision. The size of your workspace, types of projects, and air circulation requirements are critical. For instance, a well-ventilated small paint booth can enhance paint adhesion and finish quality. Yet, are you considering all your needs? It’s easy to overlook essential features like filtration systems.

Selecting the perfect small paint booth requires balancing budget constraints and desired performance. A cheap option may save money now but could lead to costly inefficiencies later. Pay attention to your specific demands to avoid dissatisfaction. Reflect on your long-term goals, as the right small paint booth could elevate your work to professional standards.

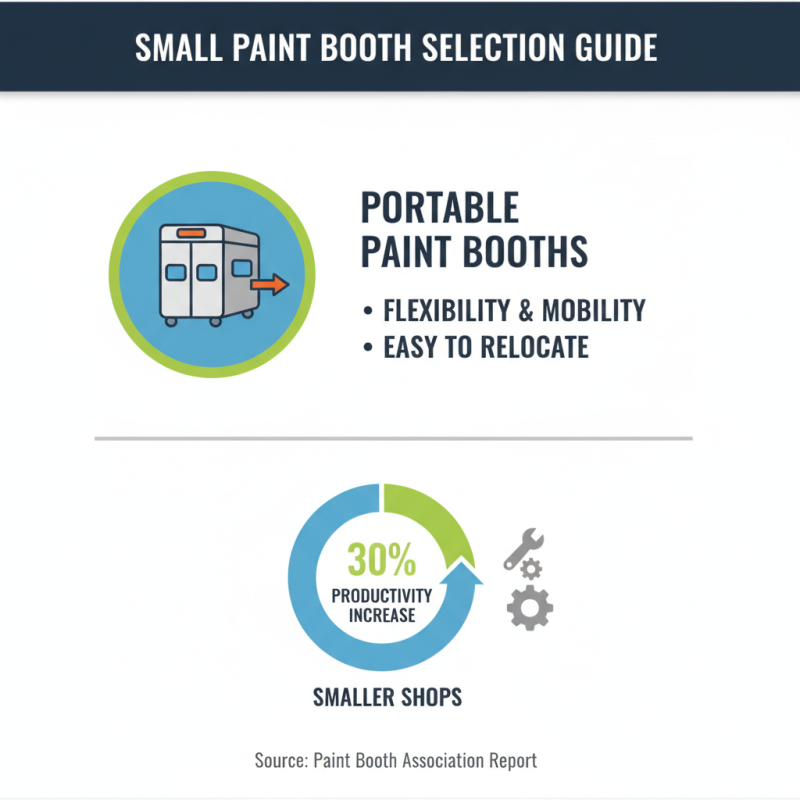

When selecting a small paint booth, understanding the types available is crucial. There are various designs catering to different needs. For instance, portable paint booths are favored for their flexibility. Many users appreciate being able to relocate them as required. A report by the Paint Booth Association shows that portable options increase productivity by 30% in smaller shops.

Another common type is the downdraft paint booth. This design uses airflow to control overspray and maintain a clean environment. Industry studies recommend downdraft systems, particularly in environments where contamination is a concern. These booths can reduce VOC emissions by up to 50%, crucial for regulatory compliance.

However, the choice is not always clear-cut. Each booth type has its drawbacks. Portable booths may lack sufficient airflow, while downdraft booths can be more costly to install. Some users find that their first choice does not always meet expectations. It’s essential to weigh these factors carefully when making a decision. Make sure to assess your specific needs and workspace limitations to choose the right booth for optimal results.

When evaluating space requirements for a small paint booth, start by measuring your workspace. Take note of the ceiling height and floor area. A paint booth needs adequate ventilation and space for equipment. Consider the distance between the booth and any walls. This helps ensure proper airflow.

Think about the types of projects you'll take on. Are they small pieces or larger structures? A small booth might work if projects are limited in size. However, if you often handle larger items, a bigger setup may be necessary. Keep in mind that cramped space can limit your creativity and make workflow inefficient.

Visualize how you will access the booth while working. Having enough room to move around the booth is crucial. If the layout feels tight or cluttered, it may hinder your process. An uncomfortable setup can be frustrating and impact the quality of your work. Always allow for some flexibility in your design.

When choosing a small paint booth, focus on key features for optimal performance. A high-quality filtration system is essential. This feature ensures that dust, particles, and harmful fumes are effectively removed. Without proper filtration, your work may suffer.

Consider the booth's size and layout. It should provide enough space for your projects without feeling cramped. An overcrowded environment can lead to accidents and poor paint application. Aim for a design that allows easy movement around the workspace.

Tips: Ensure easy access to power sources. This allows for a smooth workflow. Check for adjustable airflow settings too. Different projects may require varying levels of ventilation. Assess the materials used in the booth's construction. They should be durable and fire-resistant. Your safety relies on it.

When selecting a small paint booth, airflow and filtration are crucial aspects to consider. Efficient airflow helps maintain consistent temperature and humidity levels. A well-designed airflow system can reduce overspray, which minimizes waste and ensures a smoother finish. You want to feel the breeze when you enter. If it’s stagnant, chances are your booth needs reevaluation.

Filtration is equally important for paint booth efficiency. High-quality filters capture harmful particles and vapors. This protects both the environment and your health. Make sure to check the filter's MERV rating. Higher ratings mean better filtration. Regular maintenance is essential. Neglecting to change filters can lead to poor performance. This could compromise your work and safety.

Additionally, consider your specific needs. Some projects may require more airflow, while others might prioritize filtration. Analyzing your workspace and workflow can provide insights. Think about the paint types used. Do they produce more fumes or require more ventilation? Each detail matters. Small oversights can lead to big problems later on.

Choosing a small paint booth involves balancing cost and quality. You want a booth that fits your budget but also meets your specific needs. Lower-cost options may lack essential features. This can affect your painting results. A booth should control overspray and fumes effectively.

Quality booths often have better filtration systems. These systems can capture particles that lower-quality booths might miss. Paying a bit more can lead to better finishes and less wasted material. Consider the long-term value of investing in quality. Think about how often you’ll use the booth. Frequent use warrants a stronger focus on durability.

It’s important to analyze your situation. Do you have enough space? Smaller booths can fit into tighter spots, but you may sacrifice features. Reflect on your requirements before making a decision. Sometimes the cheapest option can become an expensive mistake later on. Think things through carefully.

| Model | Size (ft) | Price ($) | Airflow (CFM) | Features | Quality Rating (1-5) |

|---|---|---|---|---|---|

| Compact 100 | 4 x 6 | 1,200 | 600 | LED Lighting, HEPA Filtration | 4 |

| Pro Paint 150 | 5 x 8 | 1,800 | 800 | Adjustable Speed, Insulated Walls | 5 |

| Mini 50 | 3 x 5 | 800 | 400 | Basic Ventilation | 3 |

| Elite 200 | 6 x 10 | 2,500 | 1000 | Automated Controls, Noise Reduction | 5 |

| Budget 75 | 4 x 4 | 600 | 300 | Basic Model, Low Cost | 2 |

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.