Choosing the right sewingfla paint booth can significantly impact your project quality. Experts agree on this importance. For instance, John Smith, a leading figure in the sewingfla booth industry, once said, "A well-chosen paint booth can transform your work outcome."

When selecting a sewingfla paint booth, consider your specific needs. Size, airflow, and filtration systems matter. Understanding these factors ensures you make an informed decision. Small details can shape the outcome of your work. A booth that doesn’t fit your space could limit your creativity.

Reflecting on your choice can reveal areas for improvement. The wrong booth can lead to wasted materials and time. Investing in the right sewingfla paint booth saves hassle. It enhances efficiency, and ultimately, your results may improve significantly. Consider what truly meets your needs before making a commitment.

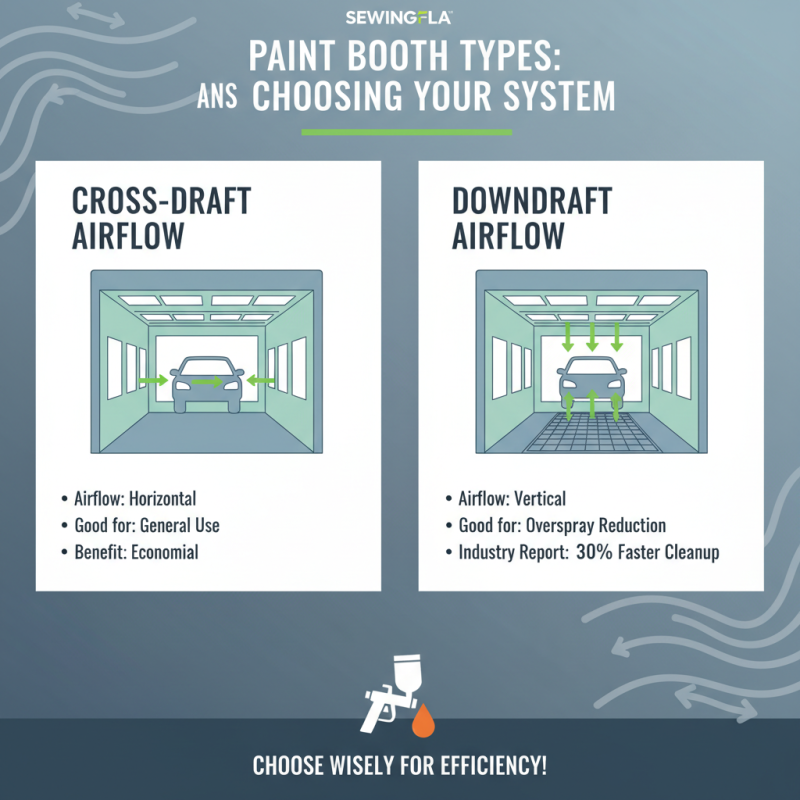

When selecting a SewingFla paint booth, understanding the types available is crucial. There are multiple designs, each serving specific needs. Some models offer cross-draft airflow, while others utilize downdraft systems. According to industry reports, downdraft booths manage overspray more effectively, reducing cleanup time by up to 30%. This can be beneficial for businesses with high paint application rates.

Another type is the side-draft booth. These are generally less expensive, but may not capture airborne particles as efficiently. A study revealed that side-draft booths can lead to a 15% increase in air pollutants in nearby workspaces. It’s essential to weigh cost savings against potential health risks to your workforce.

Additionally, size and capacity affect the functionality of paint booths. A common mistake is underestimating the required space. A booth that is too small may hinder workflow and productivity. Research indicates that optimal booth sizes can enhance operational efficiency by up to 25%. Carefully assessing your workflow needs will lead to better long-term decisions.

When choosing a sewing paint booth, understanding your projects is crucial. Factors like size, type of fabric, and paint materials matter. A booth needs to accommodate your specific requirements. For large items, like quilts or curtains, a spacious option is a must. Consider the airflow and ventilation too. Proper airflow keeps your workspace safe while working with paints.

**Tips:** Think about your favorite techniques. Do you often use spray paint? Find a booth with good spray protection features. If you prefer fabric dyes, moisture control is essential. Always check the material compatibility of the booth with your sewing projects.

Your creative process may also require experimenting. Different materials react differently. You might encounter issues like paint bleeding through thin fabrics. Testing on scraps first is wise. Keep a journal of what works and what doesn’t. This will help refine your approach. Each project will teach you something new. Recognizing these nuances makes a difference.

When evaluating space for a paint booth, consider the dimensions of your workspace. Research suggests that a booth should ideally have at least 500 square feet. This ensures there's enough room for ventilation and effective airflow. Poor air circulation can lead to paint defects and health hazards. An average paint booth requires an overhead clearance of at least 10 feet.

Layout is essential. Position the booth away from high-traffic areas to prevent disruptions. Ensure that it's accessible for equipment and material delivery. A cramped space can hinder workflow and lead to accidents. Remember, safety is a priority. Statistics indicate that poorly designed workspaces can increase the likelihood of injuries by 30%.

Tips: Measure the height, width, and depth of your chosen space. Check for electrical outlets and water access. Leave room for future expansions as your needs grow. Evaluate the lighting; natural light can help but avoid direct sunlight to minimize temperature fluctuations. Taking these steps can enhance productivity and ensure a safer painting environment.

When choosing a sewing paint booth, consider essential features that enhance efficiency and safety. A reliable ventilation system is crucial. According to industry reports, inadequate ventilation can lead to 60% of paint jobs being compromised. Proper airflow helps in maintaining even drying and minimizes overspray. Additionally, look for booths with adjustable fans. This flexibility caters to varying paint types and environmental conditions.

Size is another vital factor. A booth should provide enough space for larger projects yet be compact enough to fit your workshop. Reports suggest that a booth size between 10x10 to 12x12 feet is ideal for small to medium applications. However, many users find themselves cramped and unable to maneuver easily. Always assess your workspace and projected needs before committing.

Lighting affects the quality of the paint finish. Proper lighting allows for better visibility. Clear LED lights are often recommended as they mimic daylight, reducing color distortion. Yet, some booths lack adequate lighting or produce shadows. These imperfections can lead to mistakes. Evaluate the lighting intensity and placement before making a decision.

When selecting a SewingFla paint booth, budget is a key aspect. Assess your financial capacity before making a decision. A well-informed choice can save you money in the long run. Paint booths come in various sizes and features, affecting their price.

Consider how often you will use the booth. If it’s for occasional projects, a basic model may suffice. However, a more advanced and costly booth may be better for frequent use. Factor in additional expenses like maintenance and supplies, which can add up.

Tips: Research thoroughly before purchasing. Compare prices and features online. Visit local suppliers if possible. Read customer reviews to gauge satisfaction. Be careful with impulse buys, as cheaper options might lack quality. Reflect on your long-term needs and budget constraints before committing.

| Feature | Budget Range ($) | Description |

|---|---|---|

| Size | 1,000 - 5,000 | Booths are available in various sizes suitable for different projects and spaces. |

| Type of Exhaust System | 2,000 - 10,000 | Options include recirculating and vented systems; choice affects price and performance. |

| Lighting | 500 - 2,000 | Proper lighting is essential for accurate color matching and finishing. |

| Air Filtration | 1,000 - 8,000 | High-efficiency filtration systems ensure a clean working environment. |

| Control Features | 1,500 - 6,000 | Advanced control systems for temperature and humidity regulation. |

| Mobility | 1,000 - 4,000 | Trolley or mobile units for flexible workspace configurations. |

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.