In the rapidly evolving paint industry, choosing the right paint spray booth is critical. The global market for paint spray booths is projected to grow at a rate of 5% annually, reaching over $1 billion by 2026. This growth underscores the importance of making informed decisions when selecting a booth. With various options on the market, understanding your specific needs is paramount.

Many businesses overlook key factors when investing in a paint spray booth. For instance, air quality standards must be met to ensure worker safety and compliance. A booth that does not align with these standards may lead to costly penalties. Additionally, proper size and ventilation are crucial for achieving optimal painting results. Some may buy a booth that is too small, limiting workflow efficiency.

Selecting the right booth should not be rushed. Take time to research and evaluate features such as filtration systems and ease of maintenance. Understand that every business is unique. What works for one company may not suit another. Reflect on these aspects carefully to improve your overall painting process and production quality.

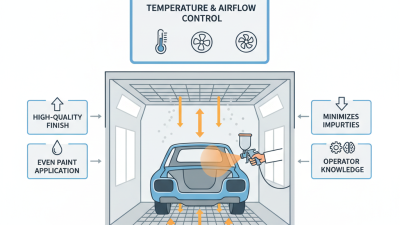

When selecting a paint spray booth, understanding air quality is crucial. Reports indicate that poor ventilation can lead to harmful exposure to airborne particles. OSHA suggests that adequate airflow reduces risks. A booth should ideally have a minimum of 100 linear feet per minute airflow. This can significantly improve worker safety and product quality.

Size matters too. A booth that is too small can restrict the movement of painters, leading to overspray and wasted materials. Industry standards recommend allowing at least 48 inches of space around the object being painted. However, many facilities overlook this detail. Ignoring space can result in poor finishes and increased rework.

Lastly, consider the types of finishes being applied. Different materials require varying levels of filtration. For example, water-based paints often need a different setup compared to solvent-based ones. Understanding these needs is essential. Yet, many operations fail to invest in the right filtration systems. This leads to increased costs from reapplications and potential health risks for workers. Always evaluate specific needs before making a decision.

When choosing a paint spray booth, understanding the different types available is crucial. There are two main categories: open-faced booths and enclosed booths. Open-faced booths are generally less expensive. They allow for easier airflow but may lack effective containment. This could lead to overspray issues and environmental concerns. Enclosed booths provide better control over emissions and safety. However, they require more space and investment.

Another critical aspect is the filtration system. Some booths use basic filters, while others have advanced systems. Advanced systems are crucial for maintaining air quality. If you often work with volatile compounds, this becomes even more important. Choosing the right filtration can prevent health risks. Assess your specific needs and working environment carefully.

Consider the layout and size of the booth as well. Space constraints can limit your options. A small workshop might not accommodate a large booth, affecting workflow and productivity. Evaluate the design of each booth. Think about access points and workflow integration. A poorly designed booth can lead to inefficiencies and frustration in operations. Reflect on what works best for your situation.

| Type of Paint Spray Booth | Best For | Size | Cost Range | Ventilation Type |

|---|---|---|---|---|

| Downdraft Booth | Automotive painting | Medium to large | $15,000 - $30,000 | Downward airflow |

| Crossdraft Booth | General-purpose | Small to medium | $10,000 - $25,000 | Horizontal airflow |

| Side Draft Booth | Furniture and cabinetry | Small | $5,000 - $15,000 | Side airflow |

| Open Face Booth | Basic projects | Varied | $3,000 - $10,000 | None (draft fans) |

| Mobile Spray Booth | On-site work | Compact | $1,000 - $5,000 | Portable ventilation |

When selecting a paint spray booth, understanding industry standards is essential. Many regulations guide the design and operation of these booths. An important aspect is ventilation. Proper airflow minimizes harmful fumes and ensures worker safety. Adhering to these standards can be challenging. Many booths fail to meet local regulations.

Fire safety is another critical concern. Spray booths must include fire suppression systems. This is often overlooked during installation. A lack of attention here can lead to dangerous situations. Inspecting these systems regularly is vital for compliance.

Noise control comes into play as well. Regulations may dictate acceptable noise levels. Outdated booths often do not meet these guidelines. Upgrading or retrofitting can be costly but necessary for compliance. It's essential to weigh the costs against potential penalties. Consideration of these factors is crucial when choosing a paint spray booth.

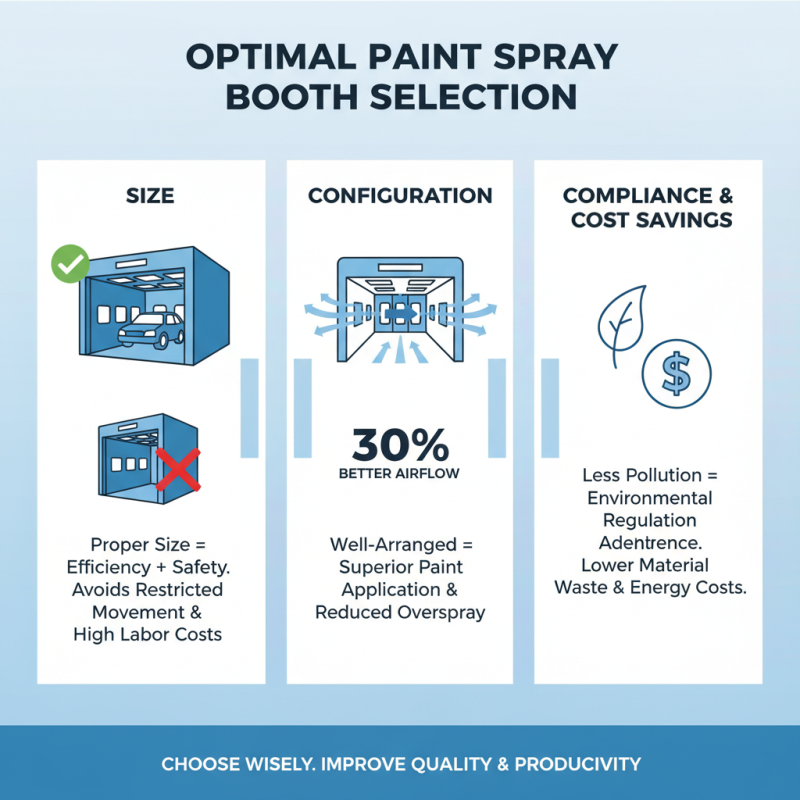

When selecting a paint spray booth, size and configuration are vital. A properly sized booth enhances efficiency and safety. Industry reports indicate that a well-arranged booth can improve airflow by 30%, leading to better paint application. This improvement diminishes overspray and pollution, crucial for compliance with environmental regulations. A booth that's too small can restrict movement, resulting in inefficiencies and increased labor costs.

Consider the layout as well. A bench-style configuration may be effective for small items. For larger pieces, a drive-in booth may be necessary. According to a 2022 survey by the Coatings Industry Association, 45% of businesses reported that improper booth sizes negatively impacted productivity. An ill-fitted booth can leave operators frustrated and unsatisfied. Realizing the potential waste of resources is essential.

Evaluating specific needs is also important. Standard sizes may not fit all operations. Custom booths can optimize workflow and enhance the user experience. A report from the American Paint Manufacturers Association highlights that custom solutions can reduce material waste by up to 20%. However, this requires upfront investment. Balancing cost and efficiency is a constant challenge for many in the industry. Reflecting on these aspects can lead to better decision-making in the long run.

When budgeting for a paint spray booth, be realistic about your costs. Firstly, consider the initial purchase price.

Paint spray booths vary in price based on size and features. Some models can be surprisingly affordable. However,

high-end booths often come with additional features. These might seem enticing but can quickly inflate your budget.

Tips: Always factor in installation costs. Improper installation can lead to operational issues, costing more in the long run. Don’t overlook maintenance fees either. A well-maintained booth performs better and lasts longer.

Another crucial aspect is the operational costs. Energy consumption can affect your monthly expenses significantly.

Booths with energy-efficient systems may have higher upfront costs but save money over time.

Research different models carefully to find the best balance.

Tip: If you're uncertain, consult with industry professionals. Their insights can help you avoid costly mistakes. You might change your mind once you see how certain features impact performance. Every choice needs careful reflection to align with your specific needs and budgetary constraints.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.