A downdraft paint booth is a specialized workspace designed to enhance the efficiency and quality of the painting process. According to leading industry expert, John Smith, who has over two decades of experience in automotive refinishing, "A downdraft paint booth not only improves air quality but also significantly reduces the risk of contamination, resulting in a smoother finish." This technology utilizes a downward airflow mechanism to draw away overspray and particles, ensuring that painted surfaces receive minimal disturbance from external elements.

The significance of a downdraft paint booth cannot be overstated, as it plays a pivotal role in meeting stringent industry standards for safety and finish quality. By channeling pollutants away from the workspace, operators can achieve consistent results while prioritizing health and environmental considerations. This is particularly beneficial in custom paint jobs, where precision and artifact-free applications are paramount.

In conclusion, the integration of a downdraft paint booth into the painting process not only optimizes the working environment but also enhances the final product's durability and appearance, making it a valuable asset for any painting facility aiming for excellence.

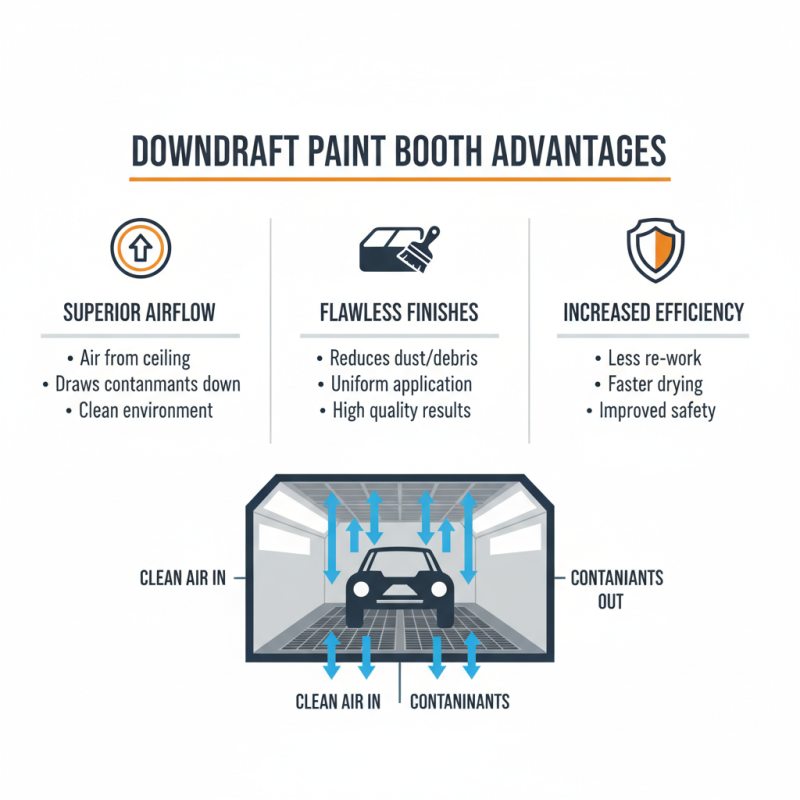

A downdraft paint booth is a specialized enclosure designed to enhance the painting process through the implementation of controlled airflow. Unlike traditional paint booths, downdraft booths utilize downward-moving air to capture overspray and particulates effectively. This system directs airflow downward from the ceiling of the booth to the floor, ensuring that paint particles are swiftly removed from the painting area. As a result, the painted surfaces achieve a smoother finish, free from contaminants that could mar the final product.

One significant advantage of downdraft paint booths is their ability to maintain a clean environment. The efficient filtration system present in these booths keeps the air clean and reduces the risk of contaminants settling on freshly painted surfaces. For optimal results, it is recommended to regularly check and replace filters to ensure the airflow remains consistent and effective.

Tips for using a downdraft paint booth include ensuring that the booth is properly sealed to prevent leaks, which can introduce unwanted debris. Additionally, always allow adequate time for the painted surfaces to dry before moving them out of the booth, as this helps avoid any damage to the finish. By following these guidelines, users can leverage the benefits of a downdraft paint booth to improve their painting efficiency and product quality.

This chart compares the efficiency of traditional paint booths versus downdraft paint booths, highlighting how the latter can improve painting processes by 20% due to better airflow and dust control.

A downdraft paint booth is designed to enhance the painting process by integrating specific components that ensure optimal conditions for both application and curing. One of the key elements is the exhaust system, which is strategically placed to draw air downward, creating a controlled environment. This helps to minimize airborne particles and contaminants, ensuring a smoother finish on the surfaces being painted. The effective airflow also regulates temperature and humidity, which are crucial factors in achieving high-quality results.

Another vital component of a downdraft paint booth is the filtration system. High-efficiency filters are utilized to capture overspray and particulates from the air, preventing them from settling on the paint job or re-entering the booth. This not only improves the quality of the finish but also contributes to a safer working environment by reducing the presence of volatile organic compounds (VOCs). Additionally, integrated lighting systems provide uniform illumination, allowing painters to clearly see their work and identify imperfections before the paint cures. Together, these components create a streamlined painting process that enhances productivity and output quality.

Downdraft paint booths are designed to improve airflow management in various painting processes, leading to enhanced efficiency and higher quality finishes. By employing a downward airflow pattern, these booths effectively capture overspray and contaminants before they settle on freshly painted surfaces. According to a recent industry report, the implementation of downdraft technology can reduce airborne particles by up to 97%, significantly minimizing the risk of imperfections in paintwork. This is particularly crucial in sectors such as automotive and aerospace, where surface finish quality is paramount.

Moreover, effective airflow management not only boosts paint application quality but also enhances worker safety by reducing inhalation exposure to harmful vapors and particulates. A study by the National Association of Safety Professionals noted that improving ventilation systems in paint booths can decrease the incidence of respiratory issues among workers by approximately 30%. Hence, investing in a downdraft paint booth not only optimizes paint performance but also promotes a healthier work environment.

Tips: When operating in a downdraft booth, ensure regular maintenance of the filtration system to maintain optimal performance. Additionally, training staff on the importance of airflow management can lead to better paint applications and increased productivity. For best results, always validate the environmental conditions within the booth to comply with safety standards.

A downdraft paint booth is a specialized enclosure designed to enhance the painting process by directing airflow downwards, effectively removing overspray and particulate matter. This design not only improves the finish quality of the paint job but also enhances the safety and efficiency of the workspace. One of the primary benefits of using a downdraft paint booth is the reduction of contaminants that can compromise the paint’s application. By utilizing a controlled environment, painters can achieve a smoother, cleaner finish that results in fewer imperfections.

Additionally, a downdraft paint booth increases productivity by allowing for faster drying times and more efficient work practices. The continuous airflow not only helps to remove excess humidity but also facilitates the rapid removal of harmful fumes and vapors. This means that workers can move through their projects more quickly while maintaining high standards of quality and safety.

**Tips for Maximizing Your Downdraft Paint Booth Experience:**

- Ensure that the booth is maintained regularly to keep filters clean and equipment functioning optimally.

- Organize your workspace with all necessary tools and materials within easy reach to minimize movement and maximize efficiency during the painting process.

- Always wear appropriate safety gear, including respirators, to protect yourself from any lingering fumes while the booth is in use.

| Feature | Description | Benefits |

|---|---|---|

| Downdraft Airflow | Air is drawn downwards, removing overspray and fumes. | Improves air quality and reduces contamination. |

| Temperature Control | Maintains optimal temperature for paint application. | Ensures better paint adhesion and finish quality. |

| Noise Reduction | Designed to minimize the noise of machinery. | Creates a safer and more comfortable work environment. |

| Increase Productivity | Allows faster drying times with controlled airflow and temperature. | Reduces downtime and accelerates project completion. |

| Versatility | Suitable for various materials and finishing techniques. | Enhances capabilities for diverse painting projects. |

When considering different types of paint booths, downdraft paint booths stand out for their unique airflow design, which significantly enhances the painting process. Unlike crossdraft or side-draft booths that create airflow from one side to another, downdraft booths direct airflow from above, pulling contaminants downward and away from the surface being painted. This not only minimizes the risk of dust and debris settling on freshly painted surfaces but also ensures a more uniform application. This controlled environment is particularly beneficial for achieving high-quality finishes, reducing the likelihood of imperfections.

In comparison to other booth types, downdraft booths also provide better temperature control and consistency. By drawing air through the booth floor and filtering it before circulating, these booths maintain optimal conditions for painting. This is particularly important in environments where temperature fluctuations can affect drying times and paint adhesion. Moreover, downdraft systems often feature advanced filtration options, ensuring that the air remains clean and suitable for sensitive operations. As a result, facilities that employ downdraft booths typically see improvements in efficiency and finished product quality when compared to those using traditional crossdraft or semi-downdraft solutions.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.