Purchasing a paint booth for sale can significantly impact your business. A well-chosen booth enhances efficiency and product quality. According to industry reports, businesses often see a 30% increase in productivity after investing in a proper paint booth. This is a crucial decision in a competitive market.

Moreover, the right paint booth can reduce paint waste by up to 25%. This translates to substantial cost savings over time. However, navigating the available options can be overwhelming. Many buyers focus solely on price, overlooking vital features that could improve workflow and safety. It’s essential to assess your specific needs carefully.

While low-cost alternatives may seem enticing, they often lack durability and proper filtration systems. Think about long-term benefits versus immediate savings. Investing in a quality paint booth for sale may seem costly upfront, but it pays off through improved operations and safety compliance. Don’t rush into a purchase; reflect on what fits your needs best.

When looking for a paint booth for sale, understanding the types available is crucial. Paint booths come in various configurations, each catering to different needs. There are open face booths, which are simpler and allow easy access but may not provide the best containment. Enclosed booths offer superior control over the painting environment. They protect against overspray and contaminants, ensuring a cleaner finish.

Portable booths are another option, allowing flexibility on job sites. These booths can be moved around, which is convenient but may compromise some features. A more permanent structure might be needed for larger operations, though this requires a higher initial investment.

Consider your space and operational scale before making a choice. Assessing airflow, filtration, and lighting is vital. Ideally, the booth should match specific project requirements. An improper match can lead to unsatisfactory results. Take time to reflect on your specific needs. Don't rush into a decision.

| Tip Number | Tip Description | Type of Paint Booth | Key Features |

|---|---|---|---|

| 1 | Determine your space requirements | Downdraft | Efficient airflow, reduced overspray |

| 2 | Consider local regulations | Crossdraft | Cost-effective, simple design |

| 3 | Evaluate ventilation systems | Semi-downdraft | Balanced airflow, low noise |

| 4 | Analyze your budget | Portable | Flexible, easy to move |

| 5 | Research different sizes | Openface | Economical, good for small jobs |

| 6 | Look for additional features | Waterborne | Environmentally friendly, reduces VOCs |

| 7 | Check manufacturer reputation | Custom-built | Tailored to specific needs |

| 8 | Consider safety features | In-ground | Space-saving, ease of access |

| 9 | Get feedback from current users | Side-draft | Effective for large items |

| 10 | Ensure ease of operation and maintenance | Combination | High versatility, multiple applications |

When selecting a paint booth, consider the size first.

A booth must fit your workspace and accommodate the projects you undertake.

Measure your space accurately. An ideal booth provides room for movement and ventilation.

Think about airflow too. Proper ventilation keeps harmful fumes at bay, ensuring a safe working environment.

Budget is crucial. Set a realistic budget and stick to it.

A quality paint booth can be an investment. However, don’t sacrifice essential features for a lower price.

Look for durability and efficiency. An economically designed booth can save costs on energy bills over time.

Also, evaluate the installation process. Some booths require complex setups while others are user-friendly.

Assess your team’s capabilities. Will you need professional help? Reflect on maintenance ease as well.

Regular upkeep ensures longevity, but it shouldn’t be a hassle. A paint booth should enhance your productivity,

not add stress.

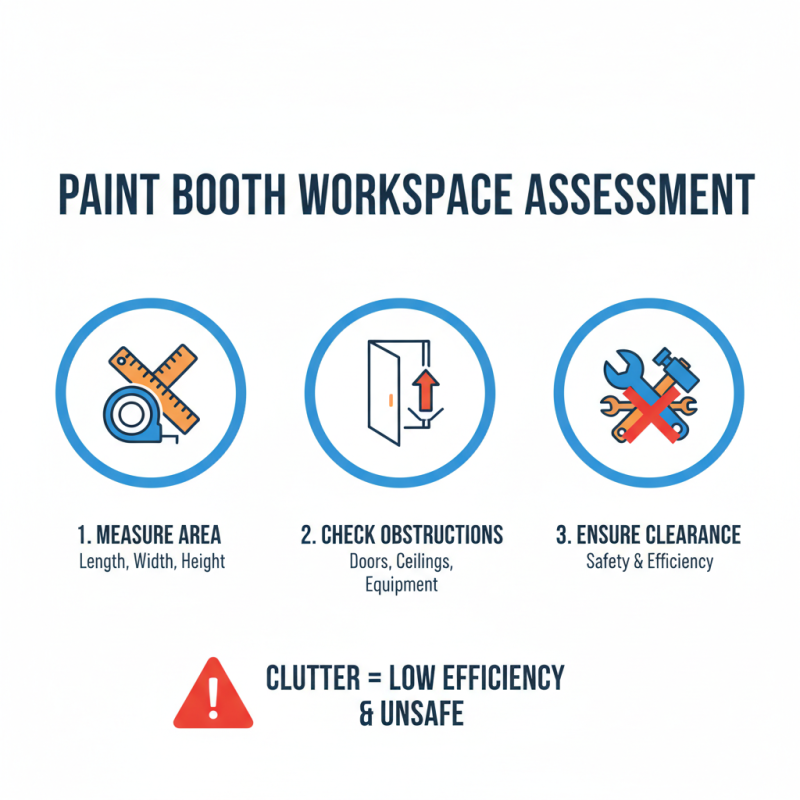

When evaluating the size and space requirements for your paint booth, start by assessing your workspace. Measure the area where you plan to install the booth. Consider doorways, ceilings, and any obstructions that may limit space. A cluttered environment can impact efficiency and safety.

Next, think about the types of projects you'll be handling. Larger items, like vehicles, require bigger booths. Smaller projects may need a compact space. It's crucial to ensure your booth fits your workflow. Sometimes, people underestimate the importance of this. A booth that's too small can lead to frustration and bottlenecks.

Don't forget ventilation. A spacious booth without proper airflow can be hazardous. The size should accommodate exhaust systems effectively. Think about future needs too. As your projects grow, you'll want more flexibility. Create a space that adapts over time. Reflecting on these details can save you headaches later on.

When buying a paint booth, safety features should be a top priority. According to the Occupational Safety and Health Administration (OSHA), proper ventilation is crucial. Paint booths need to have exhaust systems that effectively remove volatile organic compounds (VOCs). Poor ventilation can lead to harmful air quality, compromising worker safety.

Another aspect to consider is the compliance standards. Paint booths must adhere to National Fire Protection Association (NFPA) regulations. These rules outline requirements for fire prevention, including the use of explosion-proof lighting and electrical installations. Non-compliance can result in severe fines and increased risks for workers.

Furthermore, evaluating the booth's construction materials is essential. Many booths use metal enclosures that resist corrosion. Some materials may not meet safety standards, leading to unanticipated issues. It’s important to assess these features thoroughly. Potential owners should not overlook maintenance requirements either. Regular inspections are necessary to ensure ongoing compliance with safety regulations. Ignoring these could lead to serious accidents or liabilities down the line.

When budgeting for a paint booth purchase, understanding both the initial costs and ongoing expenses is crucial. The average price for a new paint booth can range from $10,000 to $50,000, depending on size and features. Buyers often overlook the additional expenses that arise with installation and compliance with local regulations. A variance of up to 15% in final costs can occur if these factors are ignored.

Ongoing costs include maintenance, utilities, and insurance. Reports indicate that operational costs can add up to 20% of the booth's purchase price each year. Electricity for heating and ventilation can significantly inflate monthly bills. For instance, a well-equipped booth may consume 300-1000 kWh monthly, costing approximately $45 to $150, based on local rates. The outdated facility might lead to higher costs over time, making regular upgrades a necessity.

Potential buyers often underestimate these financial responsibilities. It's common for companies to exceed their budgets, forcing them to make tough decisions. Evaluating long-term needs is essential. Ignoring future expenses can result in financial strain. Consider setting aside funds each month to cover these costs for smoother operations. Planning ahead may mitigate surprises that can disrupt business.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.