Maintaining your spray booth efficiency is crucial for optimal performance. A well-functioning spray booth ensures quality finishes and enhances productivity. Regular upkeep can prevent costly downtime and maximize your investment.

In daily operations, certain maintenance practices may often be overlooked. For instance, checking filters routinely is vital; dirty filters can compromise air quality. Pay attention to the airflow as well. Imbalanced airflow might lead to uneven spray patterns. Not all booths are designed the same, so understanding yours is key.

Consider the lights in your spray booth. Poor lighting can affect application precision. Some may forget to clean light fixtures regularly. Visual clarity is essential while spraying. These small details contribute to overall booth effectiveness. A little reflection on these practices will pay off significantly in the long run. Embracing a proactive maintenance mindset can transform your spray booth into a more reliable workspace.

Understanding spray booth efficiency is crucial for any industrial setup that utilizes these systems. A well-functioning spray booth can significantly enhance productivity and ensure quality finishes. Efficiency not only reduces waste but also lowers operational costs. A booth that is not operating at its peak can lead to issues like uneven finishes and longer drying times. This can hamper production schedules.

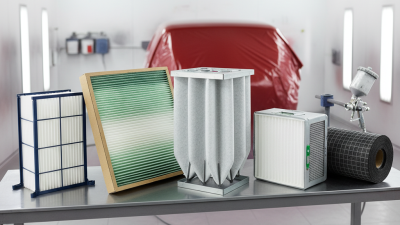

Regular maintenance plays a vital role in keeping spray booths efficient. Filters must be replaced routinely to maintain air flow. Dirty filters can create resistance, impacting performance. Inspecting the lighting inside the booth is also essential for consistent results. Dim lights can hide flaws in coatings. Additionally, operators should be trained on the equipment. Misunderstanding how to set parameters can lead to inefficiencies. It’s important to assess these aspects frequently, reflecting on what was overlooked. Effective communication among team members can identify areas for improvement. Ultimately, a focus on efficiency can prevent costly mistakes and ensure that production runs smoothly.

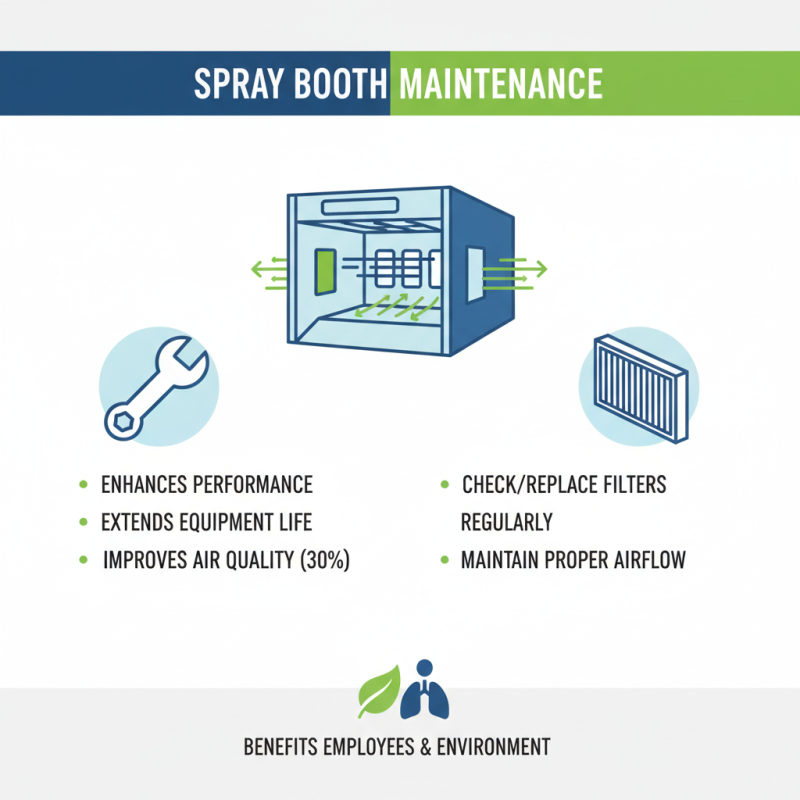

Maintaining a spray booth is crucial for operational efficiency. Regular maintenance practices not only enhance performance but can also extend the lifespan of the equipment. According to industry reports, a well-maintained spray booth can improve air quality by up to 30%, which significantly benefits both employees and the environment. Ensuring proper filtration is vital. Filters should be checked and replaced as necessary to maintain airflow.

Cleaning the booth regularly is equally important. Dirty surfaces can lead to contamination and defects in the final product. Research shows that 25% of paint defects stem from inadequate booth maintenance. Dust and residue can compromise finish quality, leading to rework that costs time and money. A structured cleaning schedule should be set, focusing on high-traffic areas and components that are often overlooked.

Inspections should also become part of the routine. Identifying potential issues before they escalate can save significant costs. Many companies ignore minor leaks or faulty lights, which can affect visibility and safety. Remember, neglecting these details can result in increased downtime and reduced productivity. Reflection on these practices is vital for ongoing improvement. Regular assessment not only leads to immediate benefits but also fosters a culture of accountability within the workforce.

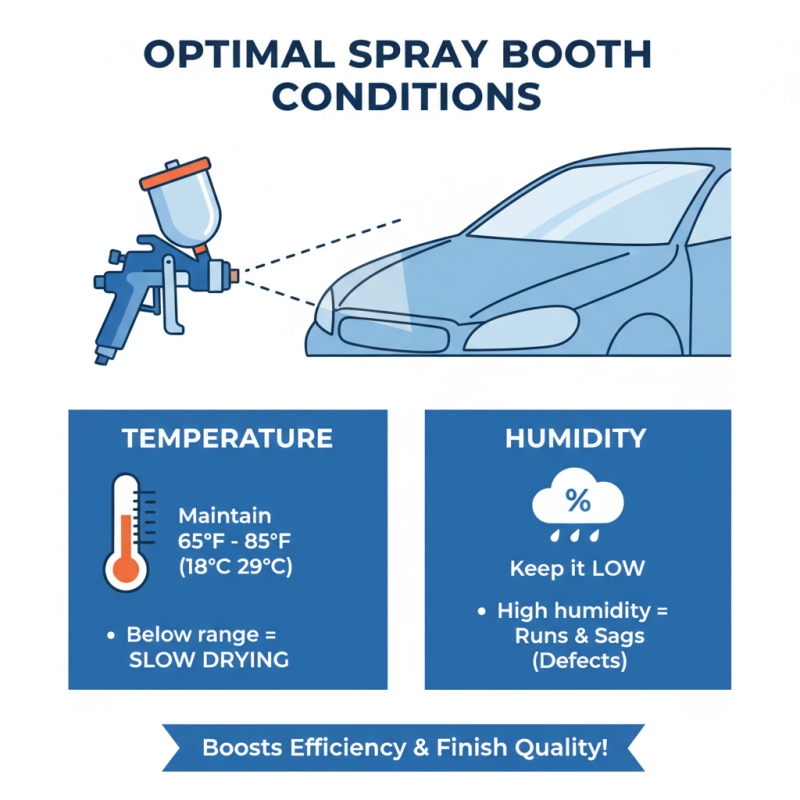

Monitoring environmental conditions within a spray booth is crucial for maintaining efficiency. Temperature and humidity directly affect the quality of applications. According to industry reports, an optimal temperature range for spray booths is between 65°F and 85°F. Dropping below this range can increase drying times significantly. High humidity can cause problems too, leading to defects like runs and sags in the finish.

Adjusting airflow is another critical factor. Many professionals overlook the importance of proper ventilation. Insufficient airflow can lead to stagnant air pockets, which affect the uniformity of the spray pattern. Ideally, air changes should occur at least 4 to 6 times per hour for effective performance. However, maintaining these levels can be challenging in fluctuating weather conditions, forcing booths to operate outside their optimal ranges.

Periodic environmental checks are necessary. Without regular monitoring, you might miss critical shifts in conditions. Sensors can help, but they must be calibrated correctly for accuracy. An inconsistent environment may indicate larger operational inefficiencies. Addressing these can improve both product quality and worker safety.

Selecting the right equipment and materials is crucial for spray booth efficiency. Your choice impacts the quality of your work and workspace environment. Start by evaluating your paint sprayers. Ideal sprayers should match the type of jobs you undertake. Using inappropriate sprayers may lead to overspray and waste.

Ensure that your booth has a proper ventilation system. A well-ventilated booth reduces fumes and ensures a safe working space. If the airflow is insufficient, it may cause inefficiencies in curing time or paint application. Regularly inspect filters and replace them when necessary. This is an ongoing task that could easily slip from your routine.

Selecting high-quality materials can also boost efficiency. Cheap paints might save costs initially but can lead to frequent rework. Poor adhesion impacts the final finish. Reflect on your material choices. Are they helping you achieve high-quality outcomes? Investing time in selecting the right materials pays off in the long run.

Monitor your spray booth’s performance consistently. Sometimes, minor tweaks can lead to significant improvements. If something feels off, don’t ignore it. It’s essential to address these issues early on to maintain overall efficiency.

Implementing safety protocols is crucial for spray booth operations. Proper safety measures protect both employees and equipment. Always wear appropriate personal protective gear. Masks and gloves are a must.

To enhance efficiency, conduct regular safety training. Employees should know how to use equipment safely. Familiarity with fire extinguishers is vital. A clean booth is essential, too. Regular cleaning prevents fire hazards and maintains airflow.

Another important tip is to inspect ventilation systems regularly. Blockages can reduce efficiency and increase fumes. Monitor air quality to ensure a safe environment. Safety should never be taken lightly. Overlooked details can lead to serious accidents. Addressing these concerns can improve both safety and production levels.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.