Inflatable spray booths have revolutionized painting and coating processes. These portable structures offer a controlled environment for various applications. Their design allows for quick setup and easy transportation, making them ideal for both large and small projects.

In industries like automotive, using an inflatable spray booth enhances efficiency. Painters can achieve a dust-free environment, ensuring high-quality finishes. The inflatable spray booth can adapt to different projects, from vehicles to delicate artwork. However, it’s essential to consider the airflow and ventilation settings. Proper management ensures optimal results and safety.

While inflatable spray booths offer many benefits, they still have limitations. Their size might restrict accessibility in tight spaces. Furthermore, they require constant monitoring to maintain the right conditions. Understanding these challenges is crucial for maximizing their potential. Each project may need unique adjustments to the setup for perfect outcomes.

Inflatable spray booths have become popular in industrial settings for good reasons. They offer a portable solution for painting and coating. These booths can be set up quickly and moved easily, fitting into various workspaces. Their adaptability is a significant advantage, especially for businesses with limited space.

Another key benefit is the controlled environment they create. Inflatable booths help in minimizing dust and contaminants. This ensures the paint adheres better and dries evenly. However, it’s important to ensure proper airflow. Insufficient ventilation could lead to uneven results. Moreover, some users have noted that assembly requires practice. It may take time to master the setup process.

The cost-effectiveness of inflatable spray booths is also noteworthy. They usually require a smaller investment compared to traditional spray booths. Companies can save on overhead costs, allowing them to allocate resources elsewhere. Still, maintenance should not be overlooked. Regular checks can prevent air leaks and wear over time. Failure to do so might impact performance. Each element, from setup to maintenance, contributes to their efficiency.

Inflatable spray booths have gained traction in the automotive refinishing industry. These booths provide a controlled environment for painting and coating, leading to improved finish quality. According to a recent industry report, over 85% of professionals prefer using spray booths to reduce dust contamination during the painting process.

They offer flexibility for shops working on different vehicle sizes. With a size range from compact cars to large trucks, these booths can accommodate various projects easily. This versatility is necessary because minor imperfections can significantly affect the overall appearance. A study highlighted that around 70% of paint defects stem from environmental factors, which inflatable booths effectively mitigate.

However, challenges still exist. The booths require proper setup and airflow management. Incorrect usage can lead to moisture accumulation, affecting paint adhesion. Furthermore, some users report issues with stability in windy conditions. Continuous monitoring and improvement in operational practices are crucial. Adopting new techniques and learning from these pitfalls can enhance efficiency in automotive refinishing.

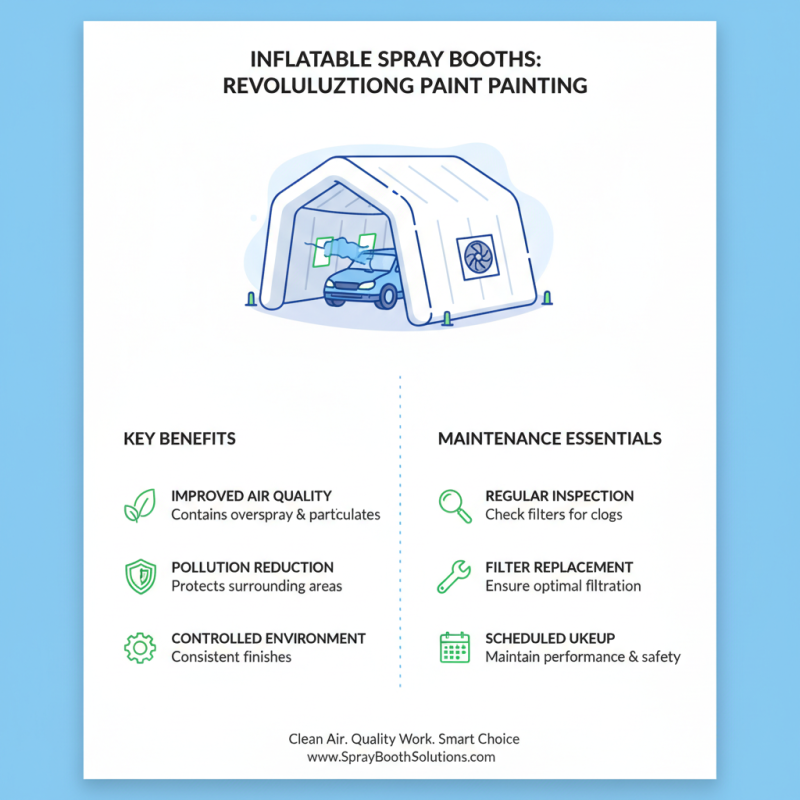

Inflatable spray booths have transformed the painting and coating industry. They provide a controlled environment that significantly enhances air quality. These structures prevent overspray and contain harmful particulates, reducing pollution in surrounding areas. However, the effectiveness of air filtration systems can vary. It's essential to regularly inspect and maintain filters to ensure optimal performance.

Compliance with EPA standards is a crucial aspect of using these booths. They are designed to minimize the release of volatile organic compounds (VOCs) into the atmosphere. Many environments still struggle with achieving full compliance. Sometimes, inadequate ventilation or old equipment can lead to breaches of regulations. Regular training for operators on best practices can help mitigate these issues.

Attention to detail in setup also matters. Booths must be placed according to local air quality guidelines. Weather conditions can impact their performance, especially during extreme temperatures. Ensuring all exhaust systems function correctly can be challenging but is vital for meeting compliance standards. Each step in maintaining these booths represents a responsibility that requires diligence and foresight.

Inflatable spray booths offer a cost-effective solution for painting and coating tasks. They are significantly cheaper than traditional spray booths. Traditional options often require substantial upfront investment. In contrast, inflatable booths are portable and easy to set up. This versatility helps save costs on installation and maintenance.

One notable cost-saving feature is the reduction in operational expenses. Inflatable booths consume less energy, which results in lower utility bills. Furthermore, they minimize the need for expensive ventilation systems. Some users may find challenges with durability, especially in harsh conditions. However, many appreciate their ease of use and quick deployment.

Another aspect to consider is the speed of setup during projects. Inflatable booths can be inflated in minutes, allowing for quick transitions between tasks. This reduces downtime, a huge plus in busy environments. Some may worry about stability in strong winds or bad weather. Yet, thoughtful anchoring solutions can address these concerns effectively.

| Use Case | Advantages | Cost Comparison | Flexibility |

|---|---|---|---|

| Automotive Painting | Mobile, easy setup, controlled environment | Lower setup costs vs. permanent booths | Highly portable for different locations |

| Furniture Finishing | Minimized overspray, improved air quality | Cost-effective for small businesses | Easily moved as needed |

| Aerospace Component Coating | High precision, minimized dust contamination | Reduction in waste and material costs | Adaptable for different projects |

| Industrial Equipment Painting | Durable structure, easy to clean | Affordable alternative to large stationary booths | Can accommodate large equipment sizes |

| Custom Art Projects | Creative freedom, unique designs | Less investment for artists with limited budget | Mobility enhances creative opportunities |

Inflatable spray booths are gaining traction in the coating industries due to their innovative technology. Recent reports indicate that the inflatable spray booth market is projected to grow by 7.5% annually. This growth reflects their efficiency, portability, and cost-effectiveness. They can be set up quickly in various locations, making them ideal for both small and large projects.

Trends point toward enhanced materials used in inflatable booths. Improved fabrics can withstand harsher environments and provide better insulation. This is crucial for maintaining optimal conditions during painting. Moreover, advancements in air filtration systems are reducing overspray and VOC emissions. Data shows that using these booths can cut waste by nearly 50%, leading to significant cost savings.

Tip: Always remember to assess your space before setup. Make sure it can accommodate the size of the inflatable booth. Consider wind conditions too; a stable environment ensures safety. Another tip: regularly check the booth for leaks. Even minor issues can affect performance. Proper maintenance is essential for long-lasting use.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.