In the world of automotive refinishing and industrial painting, the quality of the air and the efficiency of the spray booth play a crucial role in achieving optimal results. One of the most critical components of any spray booth system is the spray booth filters. These filters not only help maintain a clean working environment but also significantly improve the paint finish by capturing overspray and airborne particles. As we look toward 2025, understanding the top spray booth filters available on the market is essential for professionals aiming to enhance their performance and efficiency.

This guide will delve into the top five spray booth filters you must consider, highlighting their unique features and benefits. Selecting the right filters not only protects the integrity of your paint job but also extends the lifespan of your spray booth equipment, ultimately leading to cost savings and better productivity. Whether you are a seasoned professional or a newcomer to the industry, being informed about the best options for spray booth filters will empower you to make choices that elevate your painting projects to new heights. Let's explore the top contenders and what makes them indispensable for optimal performance in your spray booth operations.

When it comes to spray booth operations in 2025, efficiency and air quality are paramount. The right filters not only enhance the painting process but also contribute significantly to the overall workplace environment. High-quality spray booth filters capture airborne particulates and harmful overspray, ensuring that the air remains clean and safe for both operators and the surrounding environment. As such, choosing the right filters can make a substantial difference in productivity and compliance with health regulations.

One notable option for 2025 is the HEPA filter, known for its exceptional filtration capabilities. These filters can efficiently capture tiny particles, ensuring that the air in the spray booth is free from contaminants. Additionally, electrostatic filters are gaining traction due to their ability to attract and trap dust and particulates without impeding airflow. Selecting a combination of these advanced filters will not only maximize the efficiency of your spray booth but also improve air quality, reducing the risks associated with harmful substances in the painting process.

HEPA filters have emerged as the gold standard for air filtration in spray booths, thanks to their exceptional ability to capture airborne particles. Recognized for their efficiency in filtering out 99.97% of particles as small as 0.3 microns, HEPA filters are crucial in maintaining a clean and safe working environment.

In spray booth applications, where harmful overspray and fumes can pose significant health risks, utilizing HEPA filters ensures that air quality remains optimal, providing protection for both workers and the surrounding environment.

In addition to their filtration capabilities, HEPA filters also enhance the overall performance of spray booths. By preventing contamination of the work area and ensuring a sterile environment, these filters can improve the quality of the finished product, minimize defects, and reduce the risk of rework. Furthermore, their durability and low maintenance requirements make them a cost-effective solution for businesses looking to maximize efficiency in their operations. When considering spray booth filters, HEPA filters stand out as an essential component for any setup aiming for top performance and safety.

When selecting spray booth filters, the choice of activated carbon filters is critical for maintaining a clean and efficient working environment. These filters are specifically designed to capture odors and volatile organic compounds (V.O.C.s) released during the painting process. The porous structure of activated carbon allows it to adsorb harmful substances, effectively reducing the risk of air pollution and ensuring a safer atmosphere for workers. This capability makes activated carbon filters an essential component in any spray booth setup.

In addition to their odor and V.O.C. control capabilities, activated carbon filters can also enhance the overall performance of your spray booth. By maintaining optimal air quality, they contribute to better finish quality and consistency in painted surfaces. Moreover, these filters are often lightweight and easy to replace, making them a practical choice for businesses focused on efficiency. When considering which spray booth filters to implement, prioritizing activated carbon filters will ensure that both air quality and environmental safety are upheld.

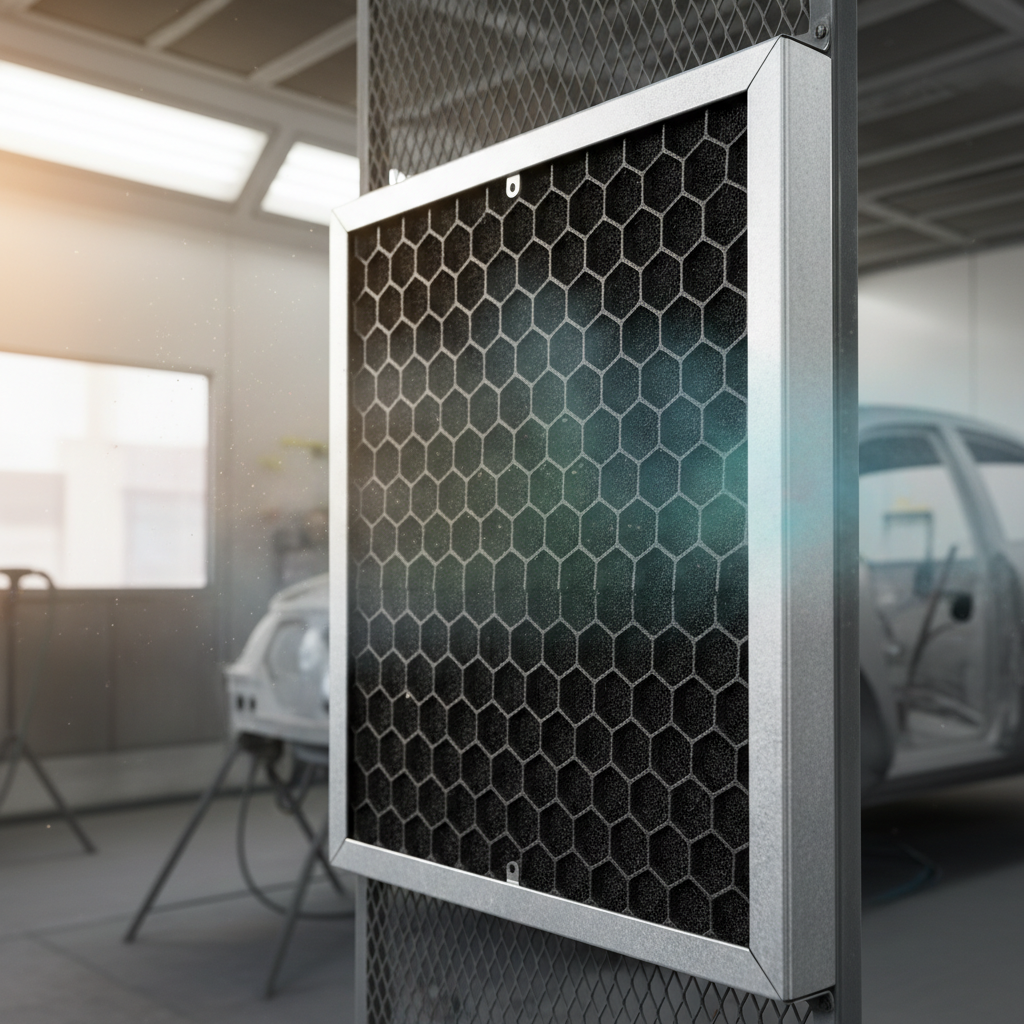

Electrostatic filters have gained significant attention in modern spray booths due to their enhanced particle capture rates, making them a top choice for industries focused on air quality and performance. These filters operate on the principle of electrostatic attraction, which effectively pulls in airborne particles that standard filters might miss. This leads to a cleaner working environment, reducing overspray contamination and improving the overall finish quality of painted surfaces.

When considering electrostatic filters for your spray booth, it’s essential to ensure proper maintenance for optimal performance. Regularly inspecting and cleaning these filters not only extends their lifespan but also ensures they continue to operate at peak efficiency. Additionally, pairing electrostatic filters with a high-quality pre-filter can significantly extend filter life and improve particle retention by capturing larger debris before it reaches the electrostatic layer.

Tips: Always check the manufacturer's guidelines for the appropriate replacement intervals for your electrostatic filters. Invest in pressure gauges that can help monitor filter saturation levels, allowing for timely replacements and maintaining air quality in your spray booth.

Ensuring optimal performance in spray booths significantly depends on effective filter maintenance. According to the Environmental Protection Agency (EPA), poorly maintained filters can result in a 20-30% increase in energy consumption due to decreased airflow, which can lead to longer drying times and compromised finishes. Regular maintenance not only helps in maintaining consistent airflow but also reduces the risk of airborne contaminants affecting the quality of the spray finish.

In addition, the lifespan of spray booth filters can be considerably impacted by proper upkeep. A study conducted by the National Institute for Occupational Safety and Health (NIOSH) suggests that consistently replacing or cleaning filters can extend their effective life by up to 50%. This proactive approach not only helps in minimizing operational costs but also enhances worker safety by maintaining lower levels of volatile organic compounds (VOCs) in the air. Adopting a diligent filter maintenance schedule aligns with best practices in the industry and promotes a safer, more efficient working environment.

In 2025, the selection of spray booth filters plays a crucial role in maximizing efficiency and ensuring optimal air quality in industrial environments. The top five filters to consider include HEPA filters, known as the gold standard for air filtration due to their ability to capture fine particles; activated carbon filters, which are essential for controlling odors and volatile organic compounds (V.O.C.); and electrostatic filters that enhance particle capture rates. Additionally, proper filter maintenance is vital for sustaining spray booth performance and longevity. Emerging trends in spray booth filtration technology also promise to shape the industry's future, highlighting the importance of staying updated on innovative solutions for improved air quality and operational efficiency.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.