In the automotive and manufacturing industries, the demand for efficient painting solutions is at an all-time high. According to data from the Industrial Paints and Coatings Industry Report, the global paint booth market is projected to grow significantly by 2026. This growth indicates a need for an ideal paint booth that meets various industry standards for performance and safety.

An ideal paint booth is not just a space; it is a crucial component. The right booth enhances paint application quality, ensures worker safety, and reduces environmental impact. Features such as proper ventilation, temperature control, and filtration systems are essential. These characteristics contribute to a clean environment and better finish quality. However, many businesses still struggle to choose the right paint booth. Overlooking the importance of specific features can lead to inefficiencies and increased costs.

Investing in an ideal paint booth requires careful consideration. Balancing budget constraints with the need for advanced features can be challenging. Businesses must reflect on their unique requirements and potential growth trajectories. A thorough understanding of these elements can lead to more informed purchasing decisions. Every choice made today impacts future operational success.

When selecting a paint booth in 2026, certain features stand out. Quality airflow is essential. It ensures even paint application. A well-designed ventilation system removes overspray effectively. This reduces contaminants in the air. A booth with adjustable airflow can accommodate various projects.

Lighting is another critical factor. Bright, uniform lighting is necessary for precise work. LED lights can enhance visibility. This makes it easier to spot imperfections. Consider the booth's size too. It should comfortably fit your projects. A cramped space can lead to mistakes.

Safety features must not be overlooked. Fire suppression systems are crucial. They protect against potential hazards. User-friendly controls make operation simpler. However, some booths may have complex setups. This could confuse new users. It’s important to ensure ease of use while maintaining safety.

Modern paint booths are essential in automotive applications. They provide a controlled environment for painting vehicles. This leads to higher quality finishes and reduced contaminants. A well-designed booth filters out dust and debris, ensuring a smoother coat. This is crucial for achieving that perfect shine.

Tips: Consider the size of your booth. It should fit your vehicles comfortably. A cramped space can lead to mistakes. Think about airflow too. Proper ventilation minimizes overspray. This not only saves material but also reduces cleanup time.

Using advanced paint booths enhances safety. They often feature fire suppression systems. This gives peace of mind while working. Lighting is another vital aspect. Good lighting helps spot imperfections during the painting process. Inadequate lighting can lead to overlooked details.

Do not ignore the need for regular maintenance. An unclean booth can negatively impact paint quality. Check filters frequently. Any buildup can lead to problems. Even the best booth needs reflection and upkeep to maintain optimal performance.

When choosing a paint booth, consider the purpose and scale of your projects. There are several types of paint booths available. Each type comes with distinct features and benefits. For instance, a downdraft booth is popular for its airflow efficiency. It helps in minimizing overspray and improving finish quality. This type generally costs more upfront, but offers long-term savings through reduced waste.

On the other hand, cross-draft booths are simpler and often more affordable. They work well for smaller jobs. However, they are less efficient in controlling dust and overspray. A recent industry report indicates that over 70% of users prioritize air quality in their selection process. This statistic underscores the importance of airflow design in achieving optimal results.

Considerations extend beyond technical specs. Efficiency can vary greatly from one type to another. A poorly chosen booth might lead to excessive time spent on prep and cleanup. Think about the training required to effectively operate certain booths. Those might not be clear at first glance but are crucial for long-term productivity. Reflect on your specific needs before making a choice.

When considering a paint booth in 2026, buyers should focus on several essential factors. First, look at the size. According to industry reports, the average booth size has increased by 15% to accommodate larger vehicles. Ensure the booth can serve your specific needs, whether for cars or industrial equipment.

Airflow is another critical aspect. A well-designed booth should have a continuous airflow system. This feature helps maintain quality and consistency in paint application. Studies indicate that effective airflow can reduce contaminants by up to 40%.

**Tip:** Check the booth’s filtration system. High-efficiency filters will save time and effort in maintenance.

Energy efficiency is also a significant consideration. Many manufacturers are now offering booths with energy-saving features. Such booths can decrease operational costs by 30%. However, ensure that this does not compromise performance.

**Tip:** Research necessary certifications. Some states require compliance with specific regulations.

Be mindful—choosing the most affordable option may lead to regrets. Investing in quality can prevent future issues.

| Model | Size (ft) | Ventilation Type | Energy Efficiency | Max Temperature (°F) | Cost ($) |

|---|---|---|---|---|---|

| Standard Booth | 12 x 20 | Crossflow | High | 150 | 15,000 |

| Downdraft Booth | 12 x 22 | Downdraft | Very High | 160 | 20,000 |

| Mobile Booth | 10 x 14 | Crossflow | Medium | 130 | 8,000 |

| Semi-Downdraft Booth | 12 x 18 | Semi-Downdraft | High | 145 | 18,000 |

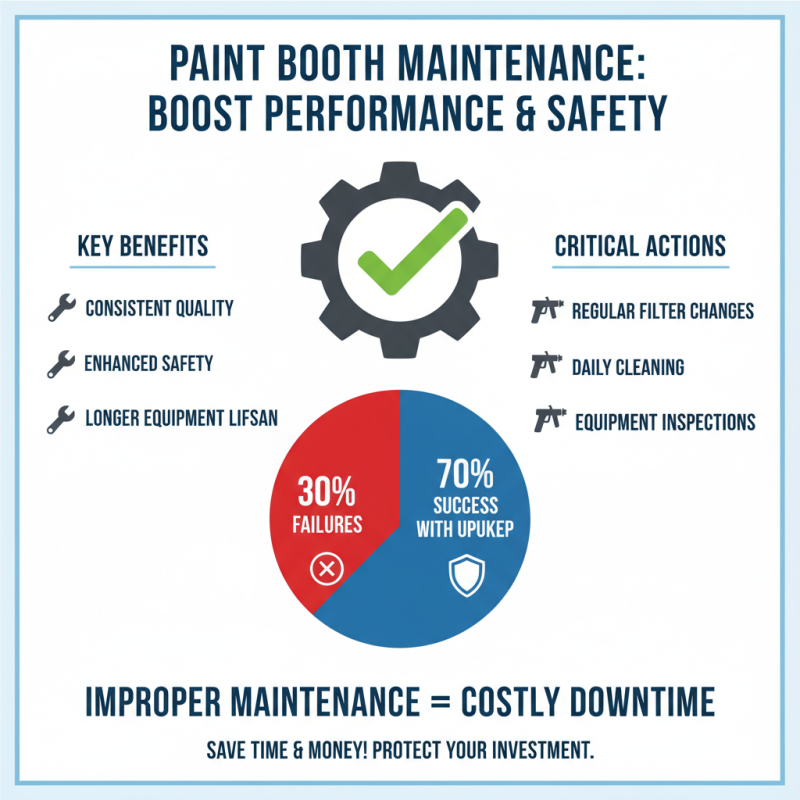

Maintaining your paint booth is crucial for optimal performance. Regular upkeep ensures consistent quality and safety standards. Reports indicate that 30% of operations fail due to improper maintenance. Understanding this can save time and money.

One essential tip is to clean your filters regularly. Dirty filters can lead to poor airflow and compromised finishes. A weekly check can prevent buildup. Dust and chemicals can settle and create issues. Use compressed air for a quick clean, or replace filters if needed.

Another important aspect is checking the lighting. Proper illumination helps in spotting imperfections during the painting process. If your booth is dim, it may lead to costly mistakes. Upgrading to LED lights is a smart choice. They last longer and provide brighter light. Remember, a well-lit booth enhances accuracy.

Finally, inspect all seals and gaskets. These components prevent overspray and help maintain the booth's environment. Cracked seals can lead to more significant problems and increased costs. Spend a few minutes each month on this task. A little effort goes a long way in ensuring your booth operates at its best.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.