When considering investments in manufacturing and finishing processes, the search for high-quality powder coating equipment for sale becomes paramount. As industries increasingly turn to powder coating for its durability and environmental benefits, understanding what to look for in this evolving market in 2025 is essential. This introduction delves into the key aspects that buyers must evaluate, ensuring they make informed decisions when selecting the right powder coating equipment.

In the rapidly advancing world of powder coating technology, features such as efficiency, flexibility, and ease of use play crucial roles. Buyers should not only focus on the equipment's performance metrics but also consider the overall value that comes with effective powder coating equipment for sale. As we navigate through the complexities of this industry, we will explore essential features, supporting technologies, and industry trends that can guide potential buyers towards making the best choices for their specific needs. With the right information at hand, investing in powder coating equipment can lead to enhanced productivity, superior quality finishes, and ultimately, a competitive edge in the market.

As powder coating technology continues to evolve, several key trends are emerging for 2025 that buyers should consider when looking for equipment. One significant trend is the integration of advanced automation and smart technology into powder coating systems. Automated machinery can enhance efficiency and reduce labor costs, allowing operators to focus on quality control and maintenance. Additionally, smart technologies equipped with IoT capabilities enable real-time monitoring and data analysis, offering insights that can lead to further optimization of the production process.

Another prominent trend is the growing emphasis on sustainability in the powder coating industry. Manufacturers are increasingly adopting eco-friendly materials and processes to minimize their environmental impact. This shift includes energy-efficient curing systems and the use of recyclable powder materials. Buyers should be on the lookout for equipment that complies with green standards, as this not only benefits the environment but can also improve a company's marketability and compliance with regulatory requirements.

Finally, customization and flexibility are becoming essential features in powder coating equipment. As industries demand more specialized coatings for diverse applications, the ability to adjust settings for different materials and finishes is crucial. Equipment that can easily switch between various powder formulations and application methods will provide significant advantages to manufacturers looking to meet the evolving needs of their clients in 2025 and beyond.

| Equipment Type | Key Features | Price Range | Market Trend |

|---|---|---|---|

| Electrostatic Spray Gun | High transfer efficiency, adjustable spray patterns | $300 - $1,200 | Growing demand for precision coating |

| Powder Coating Oven | Uniform heating, energy efficient | $5,000 - $20,000 | Increase in demand for high-capacity machines |

| Powder Coating Booth | Controllable airflow, easy cleaning | $2,000 - $10,000 | Focus on user-friendly designs |

| Powder Recovery System | High efficiency, reduced waste | $4,000 - $15,000 | Trend towards sustainability |

When selecting powder coating machines, there are several critical features to consider that can significantly impact productivity and finish quality. First and foremost, the type of application system is crucial. Machines come equipped with various application technologies, including manual, automatic, or robotic systems. Automated systems can enhance efficiency by ensuring consistent coating thickness and reducing labor costs, while manual systems may offer flexibility for smaller operations. Understanding the demands of your specific projects will help in choosing the most suitable application method.

Another vital aspect is the curing capabilities of the equipment. The temperature and time settings must align with the specific powder materials being used, as these factors directly influence the adhesion and durability of the finish. A good powder coating machine should have an efficient curing oven that can maintain consistent temperatures and accommodate various sizes of items. Additionally, consider the machine's maintenance requirements. Equipment that is easier to clean and maintain will save time and reduce downtime, leading to higher productivity in your operations. Evaluating these features will ensure that you select a powder coating machine that meets your business needs effectively.

When searching for reliable powder coating equipment in 2025, it's crucial to focus on established brands that have consistently demonstrated high performance and durability. Market leaders in the powder coating industry are known for their innovation, comprehensive warranties, and customer support. These brands typically feature advanced technologies that enhance coating quality, efficiency, and ease of use, making them ideal choices for both large-scale manufacturing and small operations.

Tips for choosing the right powder coating brand include assessing the available customer reviews and testimonials, as they provide insight into the reliability and longevity of the equipment. Additionally, look for companies that offer robust after-sales service, as this can be vital for troubleshooting and maintenance. Ensure you research the warranty options that each brand provides, as longer warranties often indicate more confidence in product durability.

Another essential aspect to consider is the range of products offered by the manufacturer. A leading brand should have a comprehensive lineup of equipment, enabling you to find compatible systems for various applications. This includes powder booths, curing ovens, and reclaim systems that can be tailored to meet specific needs, ensuring that whatever project you undertake, the equipment will support your goals effectively. Always prioritize brands that can adapt to market changes and technological advancements, ensuring their equipment remains relevant and efficient for years to come.

This chart represents the performance metrics of various powder coating equipment brands in 2025, including efficiency, customer satisfaction, and market share. The data reflects the market leaders based on customer feedback and sales performance.

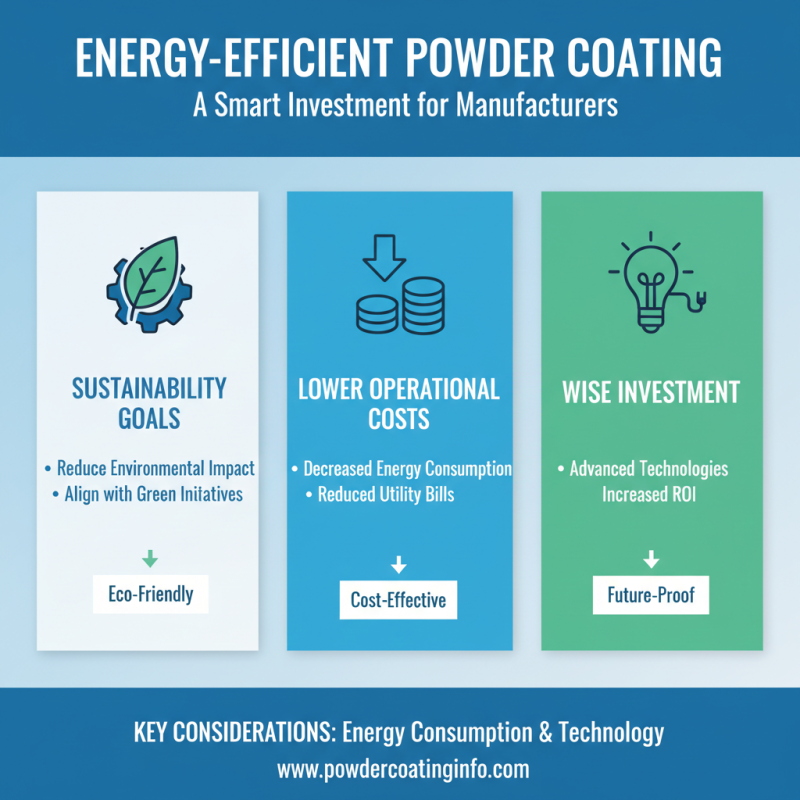

In the quest for efficient powder coating systems, energy efficiency has emerged as a critical standard to consider. As industries evolve, equipment must not only meet operational demands but also align with sustainability goals. Energy-efficient powder coating equipment can significantly lower operational costs and reduce environmental impact, making it a wise investment for manufacturers. When selecting machinery, it's essential to evaluate its energy consumption and the technologies used to enhance efficiency.

Tips for evaluating energy-efficient equipment include researching devices with advanced heating technologies that minimize energy use while maximizing output quality. Look for systems that feature insulation to maintain optimal temperature during curing, as this can drastically reduce energy wastage. Additionally, consider equipment that includes automated features for monitoring and controlling energy use, ensuring that systems operate at peak efficiency.

Ultimately, a crucial aspect of modern powder coating equipment is its ability to comply with evolving energy efficiency standards. Staying informed about regulations and technological advancements can help businesses make informed decisions, ensuring sustainability and competitiveness in the market. Emphasizing energy efficiency not only contributes to cost savings but also enhances corporate responsibility and brand image in today’s eco-conscious marketplace.

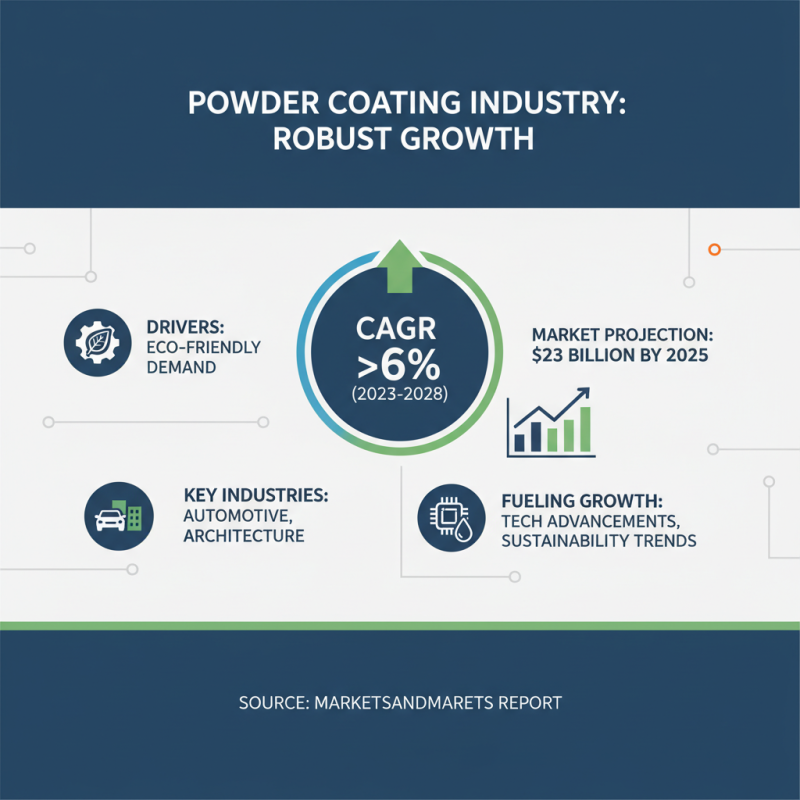

The powder coating industry is experiencing a robust growth trajectory, with projections indicating a compound annual growth rate (CAGR) of over 6% from 2023 to 2028. This significant expansion is driven by an increasing demand for environmentally friendly coating solutions, which resonate well with industries ranging from automotive to architecture. According to a recent report by MarketsandMarkets, the global powder coating market is expected to reach approximately $23 billion by 2025. This growth not only reflects heightened consumer awareness regarding sustainability but also the ongoing advancements in powder coating technology, making it a preferred choice among manufacturers.

When considering the purchase of powder coating equipment, it's crucial to focus on the machinery's efficiency, flexibility, and automation capabilities. As the industry evolves, many companies are looking for equipment that allows for quick changeovers and the ability to handle a variety of substrates. Investing in advanced systems can lead to reduced energy consumption and lower operational costs.

Tips: Always evaluate the return on investment when purchasing new powder coating machinery. Look for equipment that offers downtime analytics and connectivity to smart technologies, enabling predictive maintenance to ensure consistent production quality. Additionally, consider your facility's layout and ensure the equipment you choose can integrate seamlessly into your existing workflow without causing disruptions.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.