When searching for a used spray booth for sale, potential buyers should understand their options. A spray booth is essential for controlled painting environments. It ensures quality and safety in various industries.

Choosing the right booth requires careful consideration. Are you focusing on size, airflow, or filtration? Each feature impacts performance in unique ways. Customers often overlook their specific needs, leading to regret later. It’s crucial to evaluate both your current and future requirements.

Visiting a few vendors can help. Pay attention to the condition of the used units. Look for maintenance records and previous usage. Sometimes, sellers may not provide complete information. Do not hesitate to ask questions. A well-informed choice results in better investment and satisfaction.

A used spray booth serves critical roles in various industries. These structures are essential for ensuring that products receive a uniform finish. According to a recent industry report, nearly 70% of manufacturers use spray booths to enhance product quality. The right booth can help achieve desired coating thickness and minimize waste.

When choosing a used spray booth, several factors need consideration. The booth's condition is paramount; wear and tear can impact performance. Additionally, understanding the booth’s airflow system is vital. A well-designed airflow system helps in reducing overspray and toxic fumes. Data from the Environmental Protection Agency suggests that proper ventilation in spray booths decreases exposure to hazardous materials by up to 50%.

However, it's important to note that not all used booths meet industry standards. Some might lack essential safety features, which can lead to unsafe work conditions. Inspecting the booth thoroughly is advisable. Evaluating its compliance with current regulations will prevent future issues. Quality and safety should never be compromised in the selection process.

| Feature | Description | Importance |

|---|---|---|

| Size | Dimensions that accommodate specific workpieces. | Affects workflow efficiency and product quality. |

| Type of Finish | Compatibility with paint types: solvent-based or water-based. | Ensures proper adhesion and finish quality. |

| Filtration System | Type of filters that clean the air during operation. | Reduces environmental impact and improves safety. |

| Energy Efficiency | Power consumption and energy-saving features. | Lowers operational costs and environmental footprint. |

| Warranty & Service | Coverage on parts and maintenance offerings. | Ensures long-term reliability and support. |

When considering a used spray booth, several key features come into play. The booth's size is crucial. It must accommodate the largest item you plan to spray. A booth that’s too small can lead to inefficiencies.

According to a recent industry report, over 45% of users reported issues caused by inadequate space in their booths. This can affect the quality of finishes and increase operational costs.

Ventilation is another major factor. A well-ventilated booth ensures proper airflow, aiding in the drying process and reducing harmful fumes. Studies show that optimal airflow can enhance drying times by up to 30%. Inspecting the exhaust system is essential. A worn or inefficient exhaust can lead to poor performance and safety hazards.

Also, consider the booth's condition. Look for signs of wear and tear, particularly in the filter system. Filters in poor condition may not capture overspray effectively. Regular maintenance, such as replacements and cleanings, is required for best performance.

A staggering 60% of spray booth operators skip these routine checks, potentially leading to costly repairs. Seek a balance between price and condition to avoid future regrets.

When considering a used spray booth for sale, understanding industry standards is crucial. Compliance with safety norms protects both the workers and the workspace. Make sure the booth meets local regulations on ventilation and emissions. These standards help prevent hazardous air pollutants from affecting the environment. Air quality is a key concern.

Look closely at the booth's features. A good spray booth should have appropriate filters and fans. Inspect the lighting as well. Poor visibility can lead to mistakes during painting. Each element plays a role in achieving a quality finish. If the booth shows signs of wear, consider what needs replacement. Sometimes, a low price means high hidden costs.

Ask for maintenance history. A well-maintained booth can serve you longer. Reflect on the booth's size and design too. It must fit your workshop layout and workflow. An ill-fitting booth can cause inefficiencies and safety hazards. The right choice is not just about the price; it’s also about safety and utility.

The market for used spray booths has seen fluctuations recently. Prices vary widely depending on the model and condition. Buyers often face challenges when evaluating options. Some booths may have more wear and tear than expected. This makes it crucial to inspect carefully. Features like ventilation and size influence pricing directly.

Availability also changes based on demand. Popular models can sell quickly, leaving buyers scrambling. Less sought-after options may linger, but they often come at a lower price. Buyers need to balance cost with quality. A lower price might mean repairs are needed soon. It's important to weigh these factors seriously.

Many buyers overlook the importance of knowing the spray booth's usage history. Some booths might have been heavily used in production environments. This can lead to hidden issues that are hard to assess. Taking time to ask questions and gather information is critical. A thorough inspection can save future headaches. In the end, the right choice requires patience and diligence.

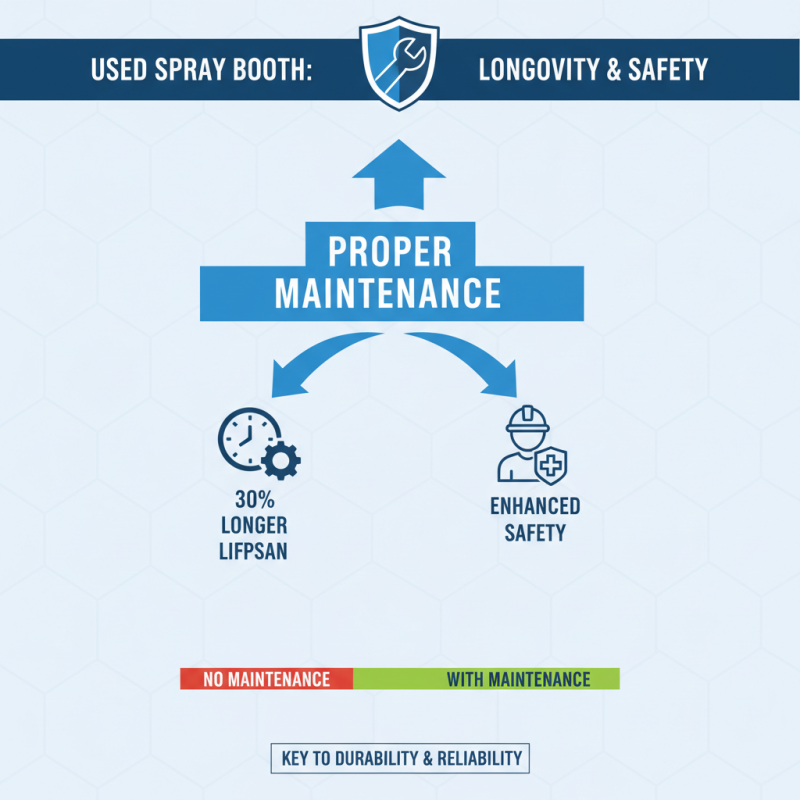

When considering a used spray booth, maintenance is crucial for longevity. Regular upkeep not only prolongs its life but also ensures safety during use. According to industry studies, proper maintenance can increase the lifespan of a spray booth by up to 30%.

One key aspect of maintenance involves ensuring that filters are clean and replaced regularly. Clogged filters can hinder airflow and compromise the quality of the paint application. Inspecting the booth for leaks is also critical; even small leaks can cause harmful fumes to escape, which poses health risks.

Keep the booth clean. Dust and debris can affect painting quality. A weekly cleaning schedule can help maintain optimal conditions. Monitor the temperature and humidity levels as well, as these can impact the drying time. Neglecting these details may lead to poor results and wasted materials.

Consider more detailed inspections periodically. Look for worn-out parts or corrosion, which can be signs of wear. Addressing these issues early can save money in the long run. Regular checks ensure that every component is functioning correctly, reinforcing safety and efficiency.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.